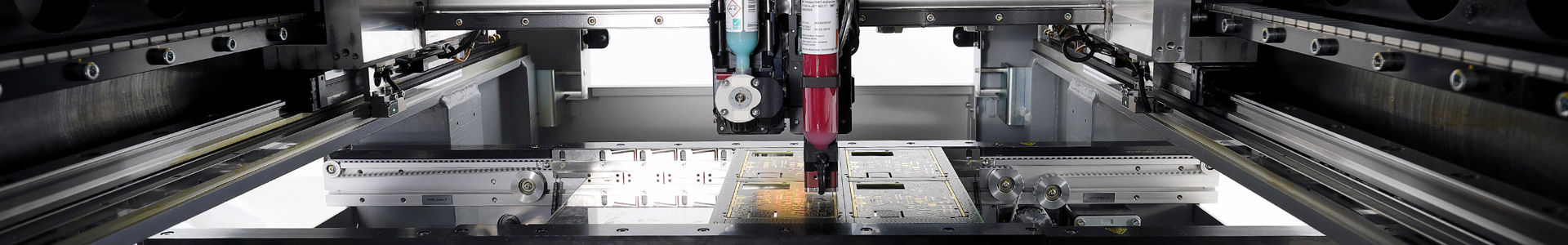

Jet printing

The future of SMT production is increasingly complex. Denser boards, a wider range of miniaturized components, more NPIs and erratic production schedules. As these high-mix challenges go mainstream, real productivity and throughput suffer. And we’ve only just seen the beginning.

At Mycronic, we’ve devoted decades of experience to solving precisely these challenges. With the industry’s fastest, most flexible and most precise jet printing and solder paste dispensing systems.

Mycronic jet printing technology makes it possible to dispense solder paste for the most challenging circuit boards and components, with micrometer accuracy, maximum speed and perfect quality solder joints.