Products

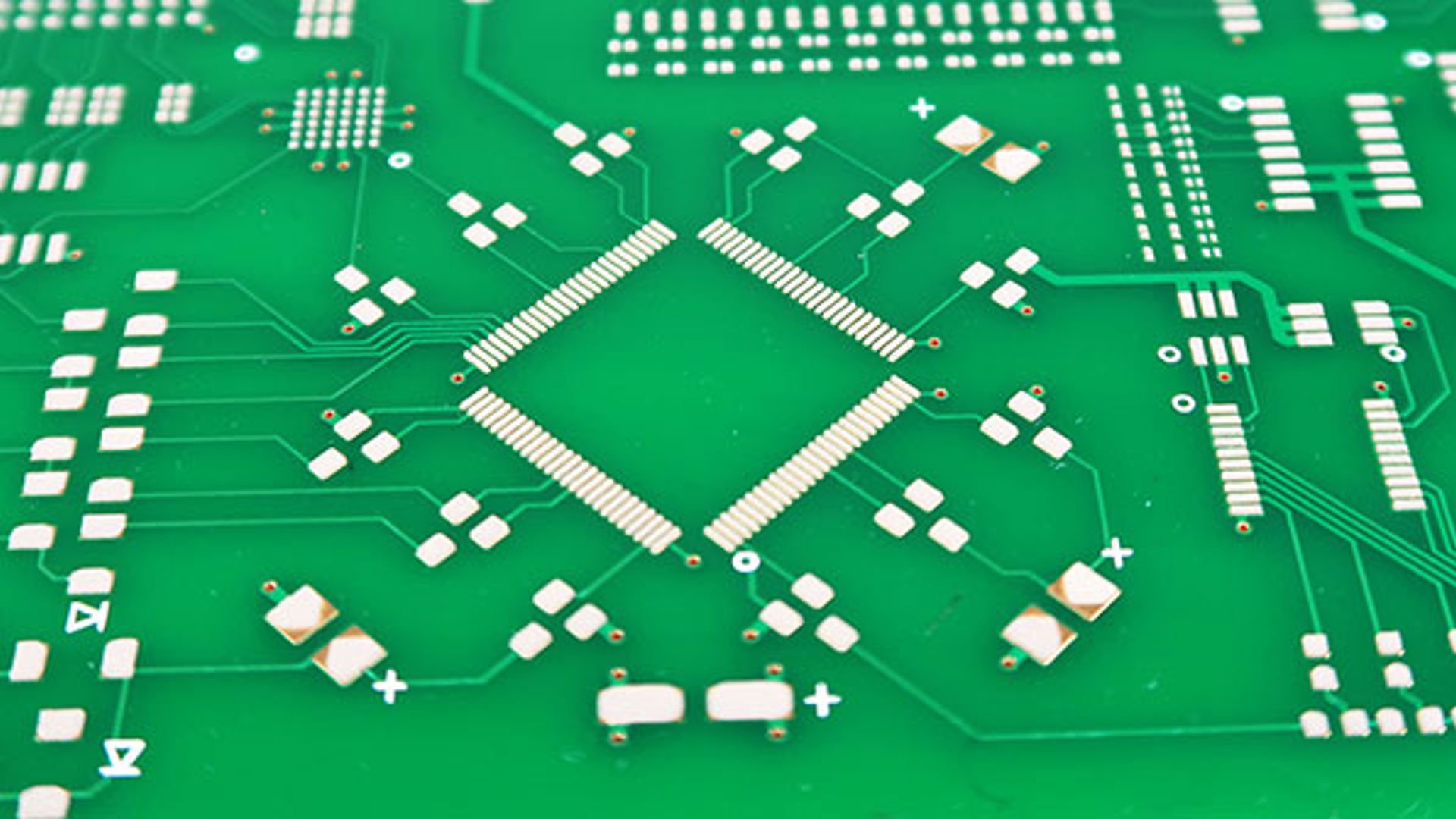

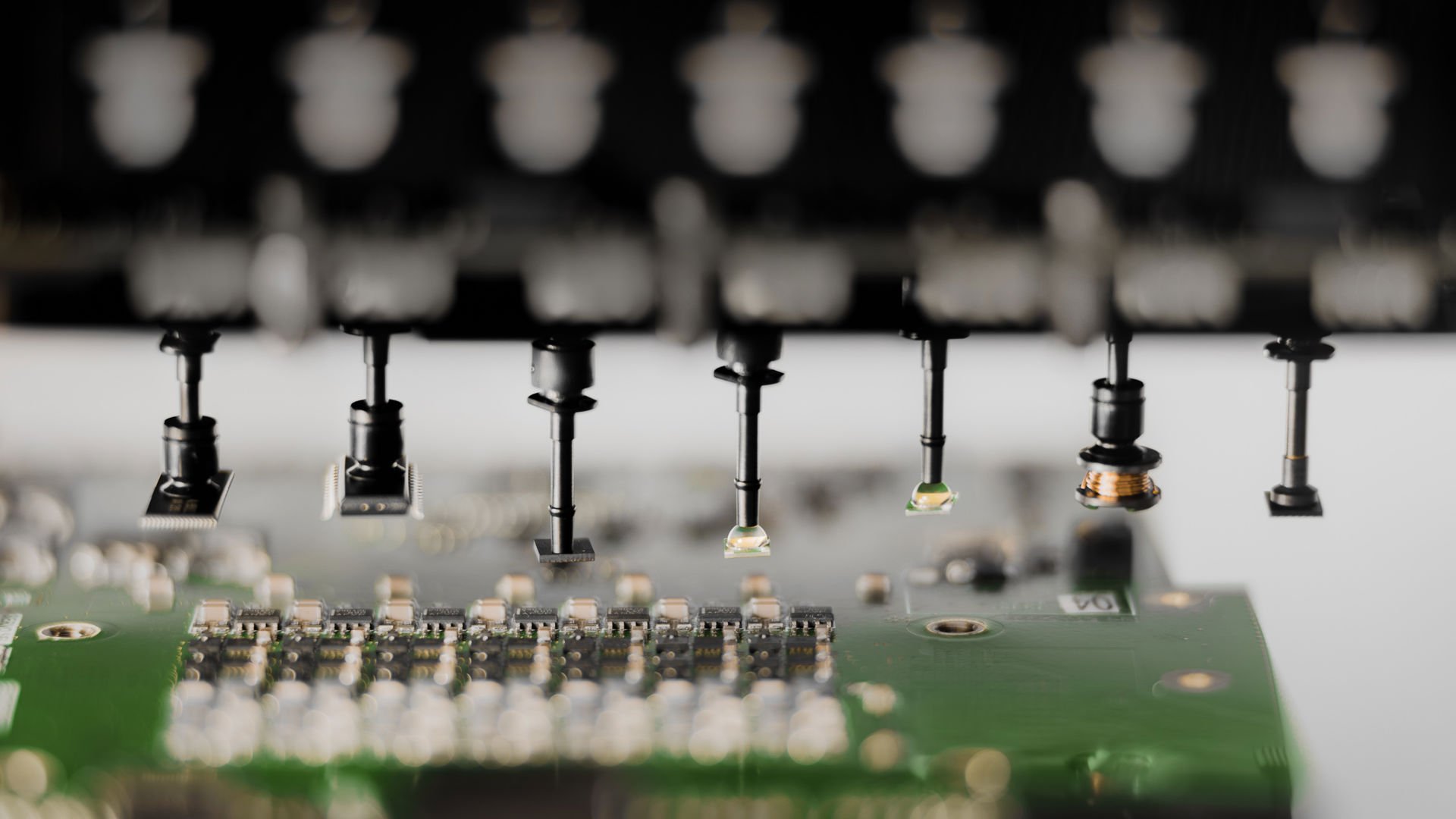

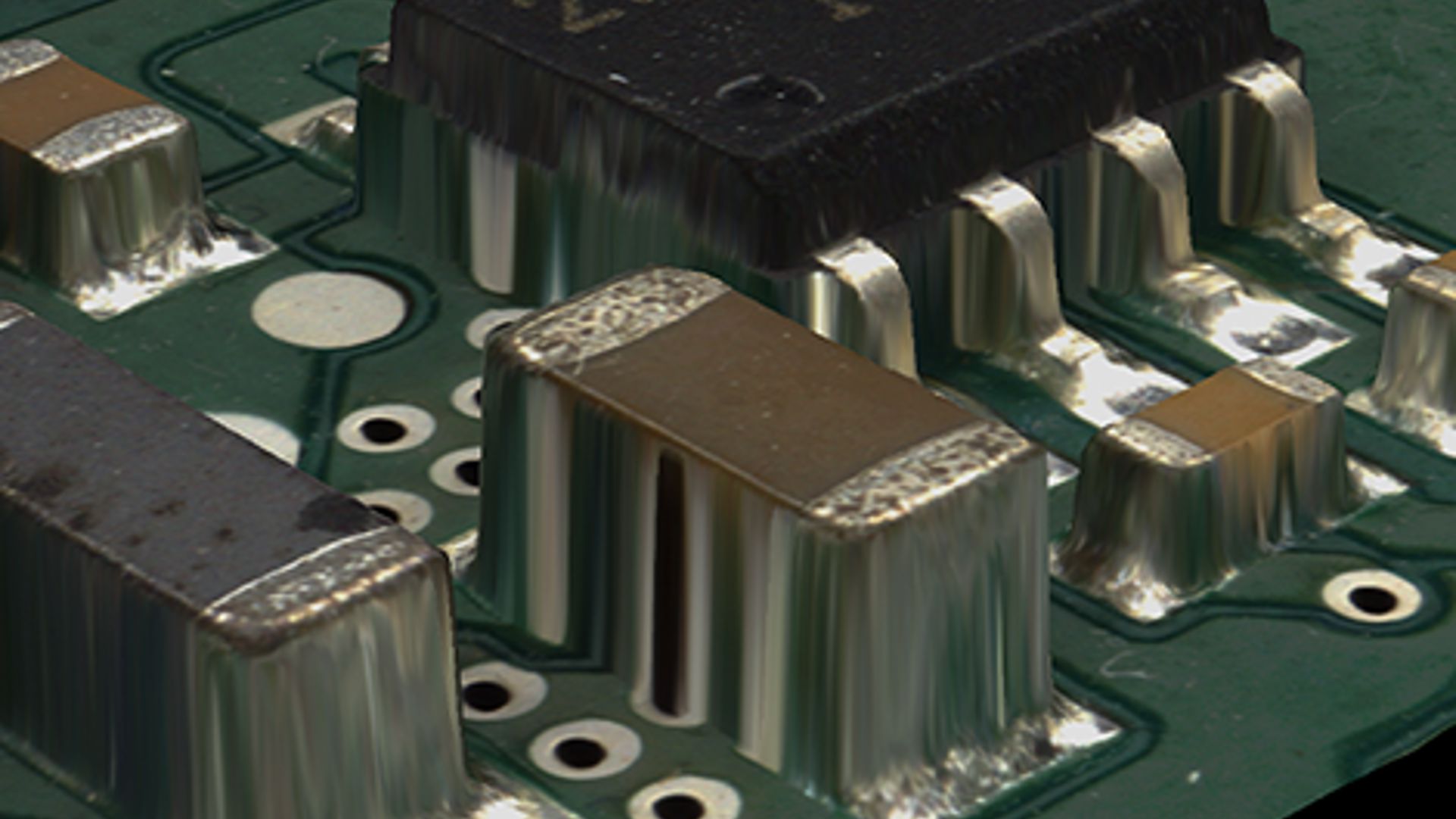

Our precision-engineered SMT machine systems deliver optimized PCB mount processes through full visibility planning, complete material tracking, streamlined changeovers, automated replenishment, enhanced product quality, and intelligent material handling.

How SMT Machines Boost Efficiency and Quality

Advanced Surface Mount Technology (SMT) systems are selected to boost production efficiency, ensure superior product quality, and lower operational costs. Designed for flexibility, speed and precision, the SMT machine products feature advanced vision systems and intelligent technology for accurate component placement. Their reliability is enhanced through predictive maintenance and real-time performance monitoring, while modular designs and customization options provide flexibility for diverse production needs. Overall, SMT solutions enable the creation of smaller, lighter, and bigger boards - both with more complex electronic products- driving greater productivity and ROI for manufactures.

Full visibility planning

- Our SMT machine systems provide comprehensive real-time visibility into your entire production process, enabling precise planning and optimization of your PCB mount operations.

- Advanced SMT machines often integrate with manufacturing execution systems or data analytics platforms, allowing manufacturers to monitor yield, downtime, and process trends.

- The flexibility supports faster troubleshooting, better quality control, and data-driven decision-making - all of which contribute to improved efficiency and reduced waste.

Complete material tracking

Advanced material tracking capabilities ensure every component is monitored throughout the SMT machine workflow, providing full traceability and inventory management.

Efficient changeovers

Minimize downtime with our intelligent changeover systems designed to optimize SMT machine setup transitions and maximize production throughput.

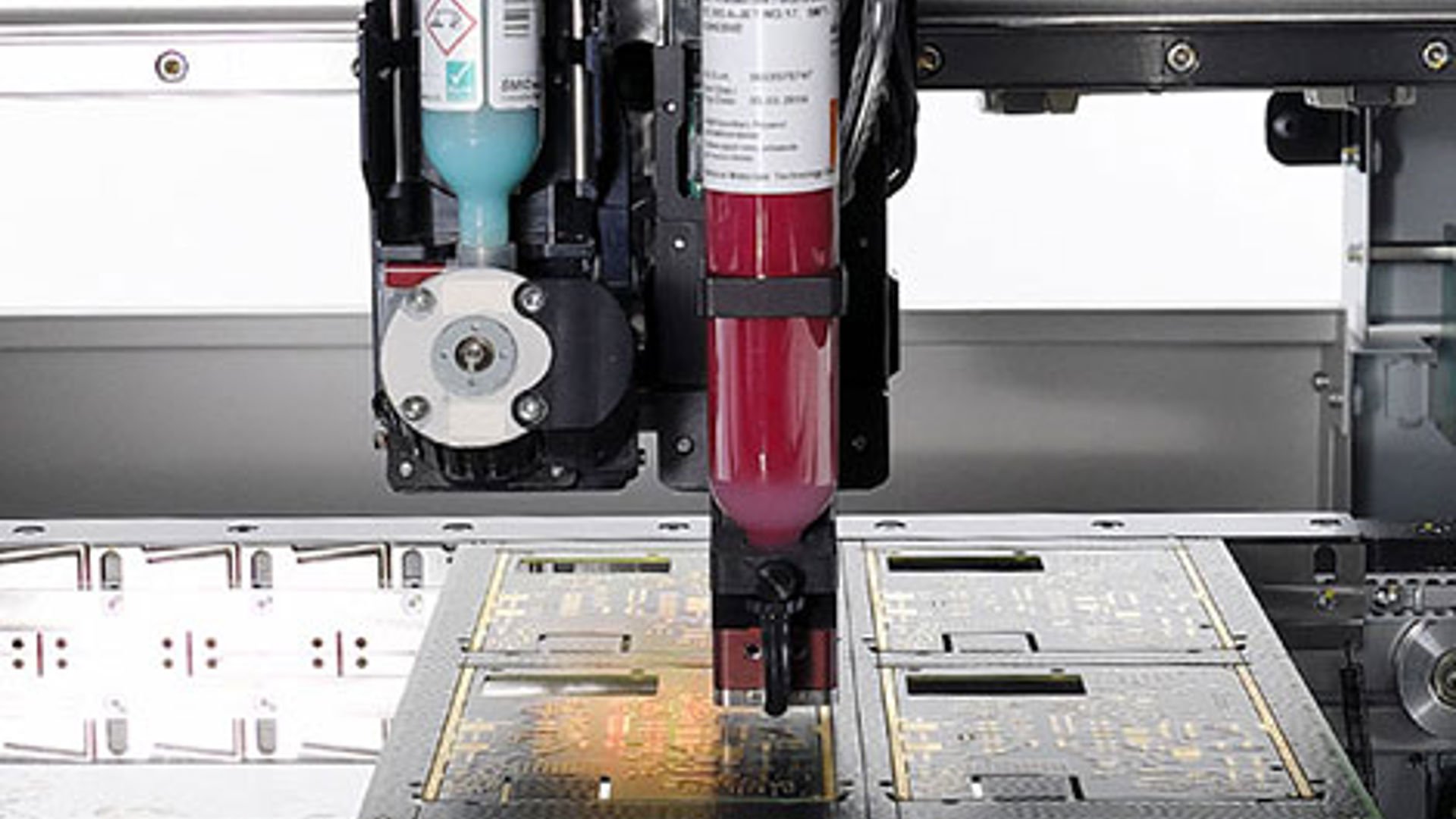

Automated replenishment

Smart automation ensures continuous operation by predicting and executing material replenishment before your SMT machine systems experience shortages.

SMT product quality

Achieve exceptional PCB mount quality with precision-engineered SMT machine technology that maintains consistent performance across all production run.

Intelligent material handling

Material handling systems are optimized for component placement and reduce waste, making our SMT machine solutions industry-leading.