MYPro I91 - 3D AOI

- AI驱动 AI驱动的接口,可实现快速可靠的编程

- 快速 检测时间缩短30%

- 准确 一流的精度

用于重型和厚板检测的高性能3D AOI

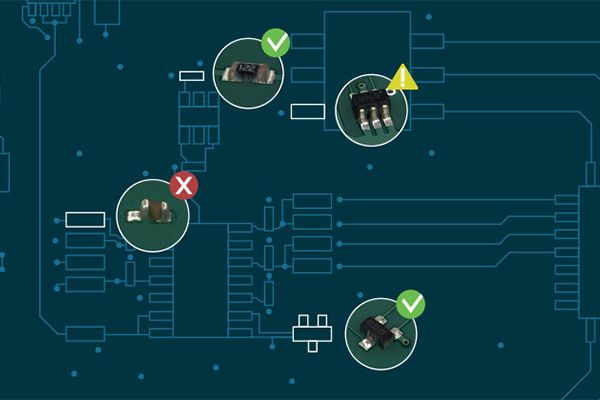

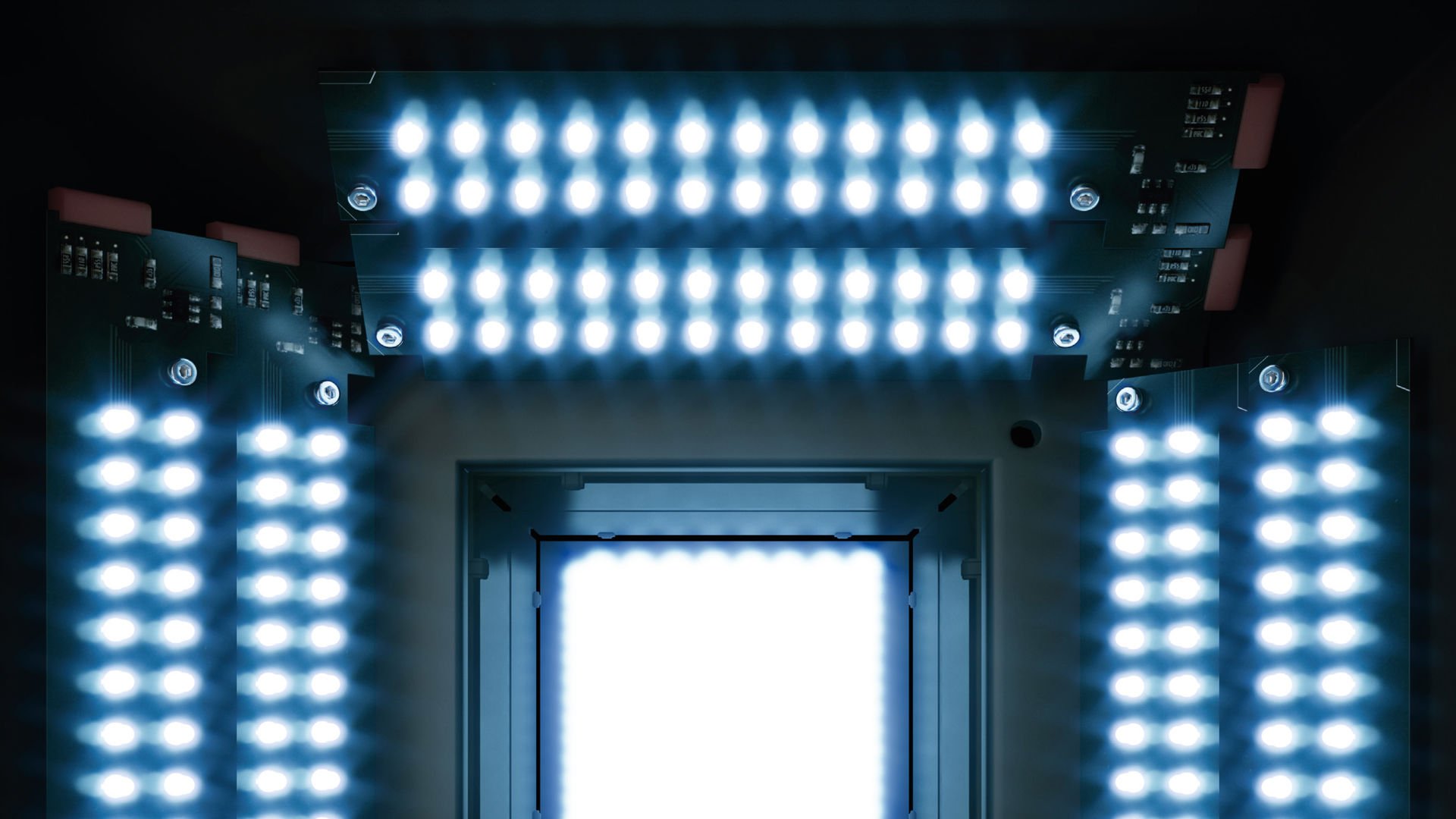

MYPro I91 3D AOI专门设计用于检测重达15Kg的重型PCBA、厚度达15毫米的特殊电路板或载具上的PCBA。例如,PCBA制造商利用MYPro I91生产电信基础设施、数据中心或高压电源管理设备。采用最新Iris™ 3D视觉技术,处理时间缩短30%,同时像素分辨率翻倍。因此,检测周期时间实现了真正的突破,与业内最苛刻的生产线保持同步,并且通过纳入对008004(0201公制)元件封装的检测进一步扩大了测试覆盖范围。

行业领先的性能和生产稳定性

MYPro I系列在X、Y、Z和Theta方向提供一流的精度和可重复性,可实现高效的工艺控制。子像素几何图案匹配技术、专有的3D算法以及独特的翘曲与失真补偿的特殊组合带来了卓越的关键测量能力。

- 矢量成像模式匹配。

- +/- 5 mm翘曲补偿,Z轴绝对精准度。

- 子像素技术,3.5 μm X/Y分辨率

- 恒定的1 μm Z轴分辨率,高度范围-5到20 mm

用于重达15kg的重型电路板检测

MYPro I91设计用于处理和检测重达15kg的重型电路板。在PCB尺寸方面,它可以处理最大533x609毫米(21 x 24英寸)的大型PCBA。

联系信息

联系Mycronic专家

在此处注册以获取有关近期活动的最新信息,最新的行业资讯和Mycronic PCB贴装解决方案的产品新闻。