Epoxy Die Bonding

Epoxy die bonding, sometimes referred to as epoxy die attach, is the most widely used die bonding technique in semiconductor assembly. Typical integrated circuits devices (ICs) have the circuitry layer built up on a base. Most of the devices interconnect to a module-level substrate by bonding a metal wire from the top surface of the IC (wire bond pad) to the surface of the substrate. Thus, the backside of the die can be used to attach the IC to the substrate using a bonding material. The most common die-bonding material is epoxy-based. Once the die is attached to the substrate in such a fashion, the assembly is usually cured, crosslinking based on a material-specific thermal profile.

Active Optical Cable (AOC) Assembly

In-line UV Assembly

Conductive and non-conductive epoxy can be applied to the substrate by a variety of methods. The material is generally filled, meaning metal particulates are suspended in a polymer matrix.

The most common epoxy die attach station consists of an automated pump dispensing system, either as a standalone dispenser station, or as a secondary function of the epoxy die bonding system. Other epoxy die bonding approaches include epoxy stamping (link to Epoxy Stamping Post) of the material, and screen printing. The properties of the adhesive composition will vary depending on the technique. Dispensing is a common epoxy die attach approach.

Thermal dissipation is another factor to be considered in epoxy die bonding. For high power devices, metal interface layers may be needed to dissipate the high amount of heat emanating from the functional IC device. In such a case, a different process of die attachment (eutectic die bonding) may be needed.

Dispensing of the Epoxy Die Attach Material

Precise volumetric control of the epoxy die attach dispensing is generally critical. The level of precision needed will drive the type of pump used. Simple air-pressure pumps offer simple mechanics for reasonable volumetric precision, at a low cost. Positive displacement pumps, and rotary auger screw pumps are two other pump types used, depending on the material being pumped and the volumetric accuracy needed. Common one-part epoxy systems generally have a short usable time span (pot life). Maintenance levels versus pump types should also be considered in the final choice.

When selecting adhesive material for epoxy die bonding, attention must be paid to the application-specific thermal and conductive specifications, normally driven by the performance requirements of the end IC module. Working with epoxy die-attach material suppliers, the process engineer can select the epoxy best suited for the specific application for epoxy die bonding. Functional trials are normally performed to establish the best candidate, generally based on tradeoffs of costs and performance, operational repeatability, and reliability classifications. Whether it will be dispensed, screened on, or stamped, the viscosity of the material and particulate size are major factors for a successful process.

Stamping of Epoxy Die Attach Materials

With all that said, there are epoxy die attach applications where dispensing is not an option. This is true in cases where the dice are so small that the amount of die attach material is below what is typically considered reliably dispensable (small laser diodes for example).

One technique consists of transferring the epoxy die attach material, from a well or from a rotating transfer disk, to the substrate. The material transfer occurs through surface tension differences. In its most basic configuration, a pin is dipped into the well. The material then wicks up the pin shaft by surface tension. When the pin makes contact with the substrate, the material is released again by surface tension. Albeit much slower than dispensing, smaller amounts of material can be transferred this way. The same transfer mechanism can be applied to more complex tools, generally referred to as epoxy die-attach stamping tools. Instead of a well, a rotating drum assembly can also be used to better control the thickness of the adhesive film from which the material is retrieved.

The material formulation for pin transfer and stamping may be quite different than the formulation used for dispensing.

Epoxy Die Bonding

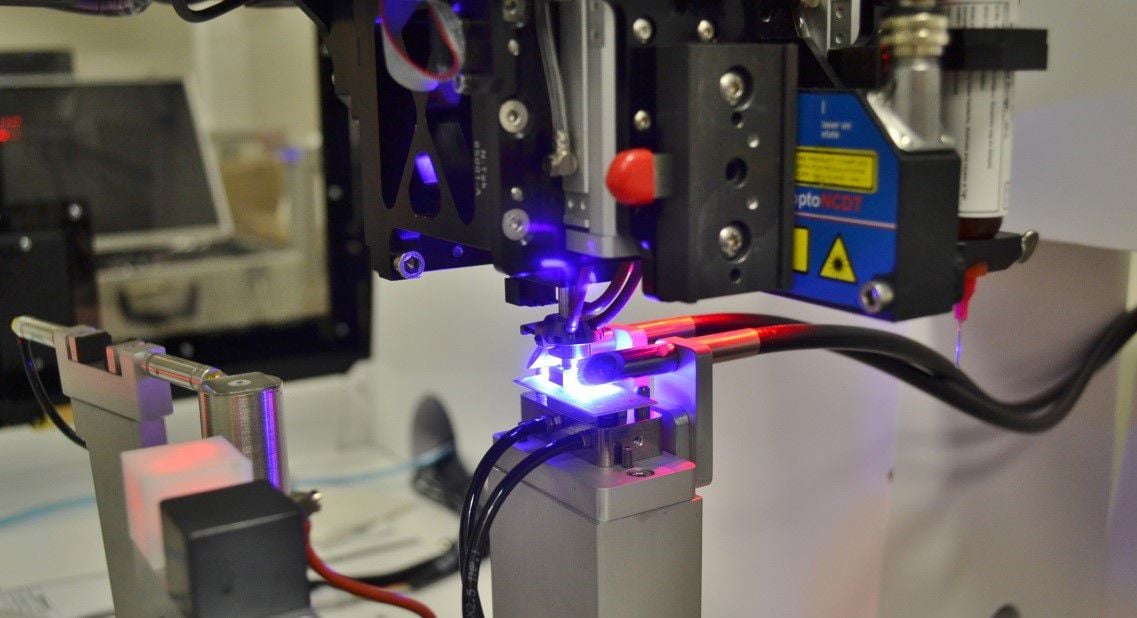

In-situ UV Bonding

As stated above, once the die is attached to the substrate in epoxy die bonding, the assembly is usually cured, crosslinking based on a material-specific thermal profile. During the die attach curing process, the die will move. The post-cure component location will have therefore shifted from its original placement location. For some advanced optoelectronics applications, this is not acceptable.

In the case of an optoelectronics transmitting device, the tolerance is so tight that active alignment of the optical signal is performed during the assembly. Because of costs, this approach is only used when no other approach works. In many applications, passively aligning the component is acceptable, provided the positional shift that occurs during curing can be eliminated. In order to do so, the component must be cured while the part is kept in location.

This “in tool” curing approach is referred to as in-situ curing. The most common approach is to use UV energy to partially or fully cure a UV-sensitive epoxy die attach material, while keeping the part in location with the placement tool. Once the adhesive is cured, further movement of the component is avoided.

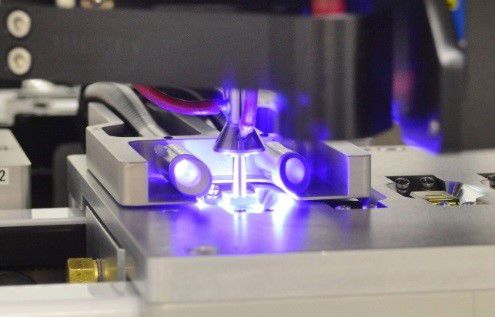

UV Probes for UV In-situ Bonding

Active Optical Cables (AOCs) are good examples of how this approach is used, since they cannot tolerate loss in die placement accuracy during the post-placement epoxy curing operation. Lenses, for example, require extremely accurate post die bond positioning to ensure optimum system performance. In such cases, In-situ UV epoxy curing is a solution. As previously described, parts are cured while held in place, eliminating the possibility of components moving as the epoxy material cures.

For such an application, the MRSI Die Bonder is configured with an optional UV curing kit, that includes specialized UV epoxy dispense hardware, as well as curing accessories. This includes easy-cleaning, accurate time/pressure dispense pumps for short pot-life materials; as well as auto-shutter light guards on the dispense needles to prevent the dispense needles clogging due to unwanted UV exposure.

Manual UV Assembly Stage