Programming just got simpler

With the new MYPro I™ series 3D AOI

Faster programming. Smarter guidance. Zero false calls. When it comes to advanced 3D AOI, demands are high and experienced operators are often in short supply. Mycronic’s latest answer is the MYPro I series 3D AOI, which leverages powerful machine learning algorithms to enable rapid programming and easy implementation of high-performance AOI for any operator in any production mix.

In recent years, Mycronic’s K series 3D AOI has excelled in processing all types of PCBs, offering complete test coverage with high accuracy and repeatability for leading high-reliability manufacturers worldwide. Now, the next-generation MYPro I series brings new levels of automation and ergonomic design to make every program easier to create, fine-tune, adapt and optimize for operators of all skill levels.

Redesigned for industry 4.0

As part of the MYPro Line family of integrated SMT solutions, the new system’s software and hardware platforms have been redesigned to provide a unified user experience. In addition to the new name, graphical user interface, and exterior design, the MYPro I series is designed to be fully compatible with Hermes and IPC CFX protocols to offer a consistent Industry 4.0 operating environment within all MYPro Line equipment.

30% faster programming

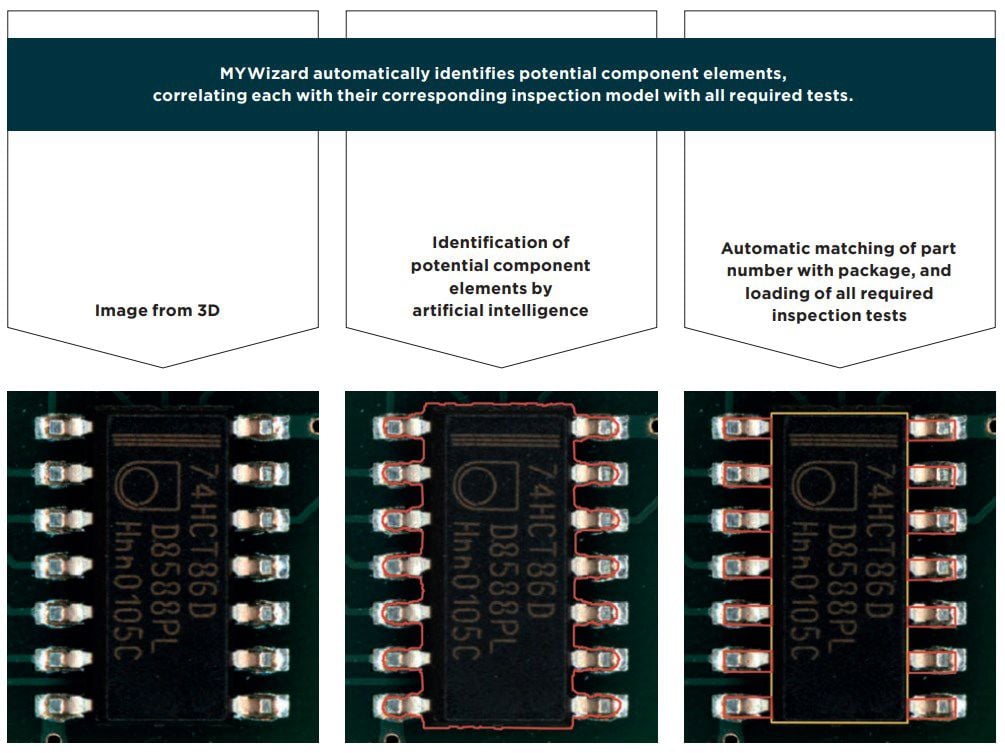

A major highlight of the MYPro I series is a new MYWizard user interface, developed specifically to guide operators more rapidly through the programming phase. Utilizing advanced machine learning, the system automatically identifies a wide range of component characteristics and correlates each with a package type from the library, thus reducing programming times by up to 30 percent, compared with the previous K series 3D AOI.

During the programming phase, features such as the board’s fiducials and the components’ body, leads and polarity marks are automatically identified. The system’s machine vision algorithm recognizes all standard components in order to automate the programming of all inspection tests to be performed.

The operator simply needs to check the MYWizard proposal, make some adjustments if necessary, and manually program any non-standard or custom components. Because all modifications are stored in a central library, programming time continues to decrease with every new job.

“The level of skill or experience required to program a 3D AOI is a real concern for electronics manufacturers, so user friendliness, ease of programming and fast implementation are all high on their agendas,” says Alexia Vey, Product Manager for product line Inspection. “Once the central library has been complemented with several products, MYWizard makes it possible for an AOI programmer with little experience to program in less than thirty minutes — which is extremely fast for a system with these capabilities.”

Automated escape tracker eliminates false calls

Recent advances in pattern recognition also make it possible to automate program fine-tuning, even as production conditions change. Thanks to Escape Tracker, a real-time performance optimizer for the system’s inspection library, the MYPro I series automatically ensures that no new false calls or escapes are introduced while fine-tuning the library to improve FPY.

“During any programming phases that require fine-tuning,” says Alexia, “Escape Tracker automatically runs in the background to monitor the generation of any potential escapes or false calls in the central library. More than that, it guides the operator in how to fix them, adding an extra level of reliability control before any modification is integrated into the central library”.

Accelerating learning curves with AI

The advanced programming capabilities of the MYPro I series have been made possible thanks to a long-term R&D program dedicated to the integration of artificial intelligence into all Mycronic inspection platforms. The benefits, including ease of use and intuitive programming guidance, were first seen years ago in the industry-leading PI series 3D SPI, and are now being fully realized in the next generation MYPro I series 3D AOI.

“These machine learning algorithms are all about teaching the system what to recognize, while also teaching the programmer exactly where the system needs human expertise,” concludes Alexia. “They make it possible to manage supply and process variations while constantly improving the reliability of the central program library — all with less and less operator skills required. Whatever your production mix, the MYPro I series accelerates this learning curve more than ever before.”

“The primary goal in developing the MYPro I series was to bring one of the most powerful 3D AOI technologies on the market within the reach of high-mix EMSs and OEMs, that need to handle large numbers of NPI jobs and short production runs”, says Jesse Dowd, VP of Global Sales Assembly Solutions High Flex. “To support this, we focused our innovation on making the programming and finetuning as simple and fast as possible. This not only benefits our traditional high-reliability, mid- to high volume customers, it also puts the possibility of advanced 3D inspection into the hands of many more manufacturers, no matter how little experience, or how many changeovers a day, they might have”, adds Jesse.