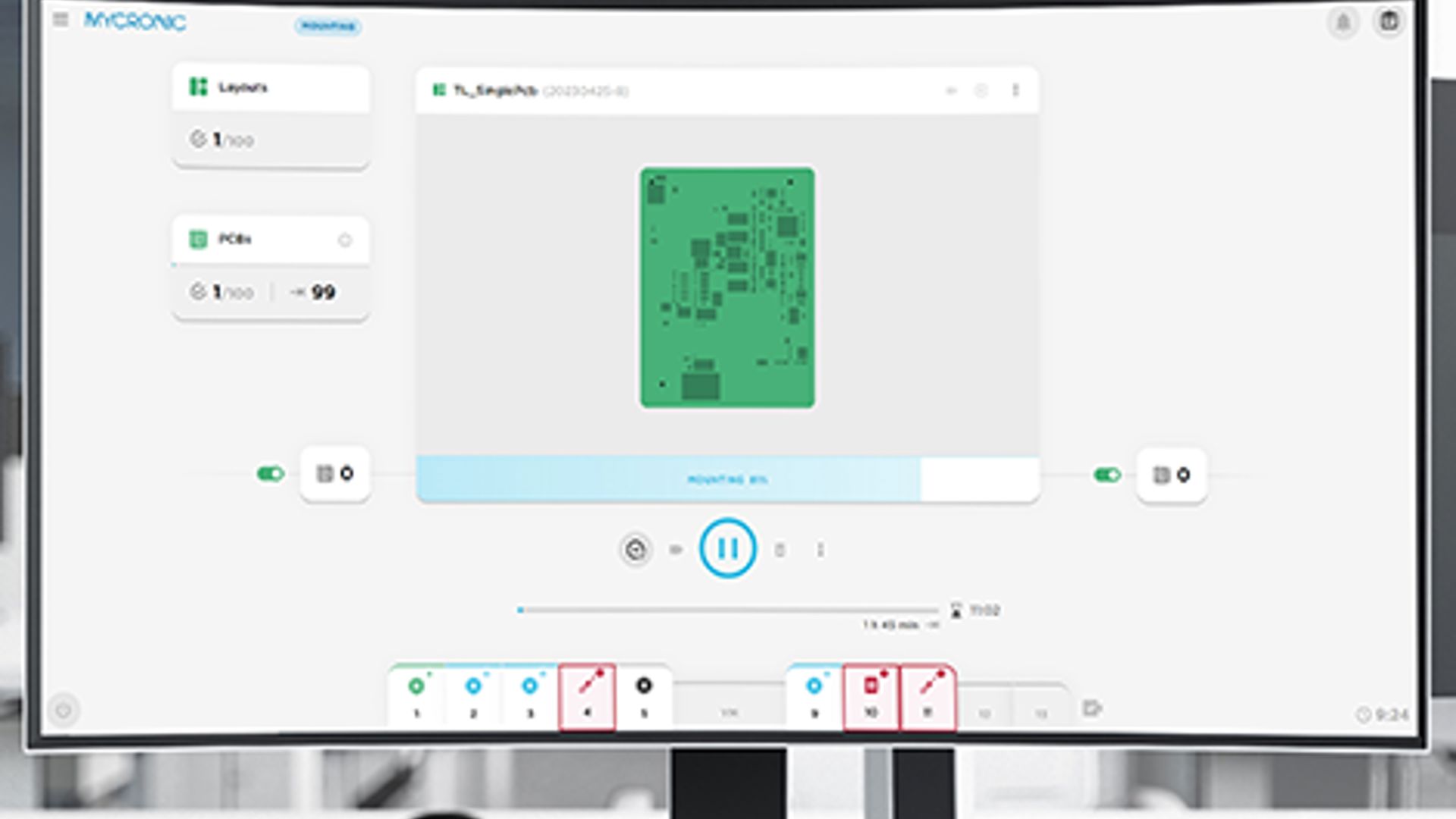

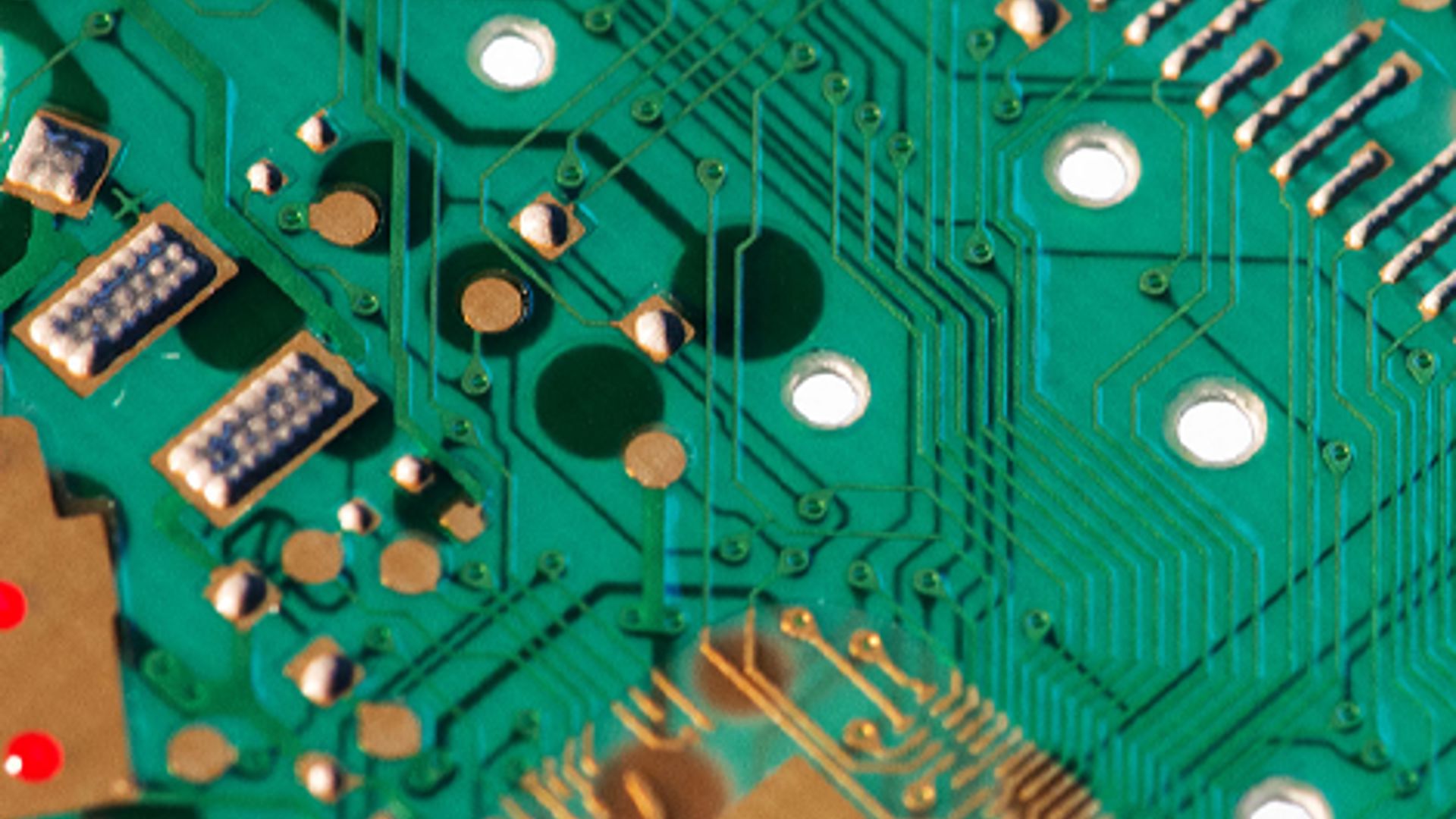

PCB贴装解决方案

Mycronic的PCB贴装解决方案为企业提供了确保以可靠和高效方式贴装印刷电路板所需的工具。

从焊膏印刷机到点胶设备,Mycronic全面的解决方案为企业提供高质量和精密的PCB贴装解决方案。

Mycronic的解决方案注重易用性和成本效益,旨在满足从小批量原型制作到大规模生产的任何规模企业的需求。

作为PCB贴装解决方案的领先供应商,Mycronic是希望将其PCB贴装业务提升到新水平的企业的完美合作伙伴。

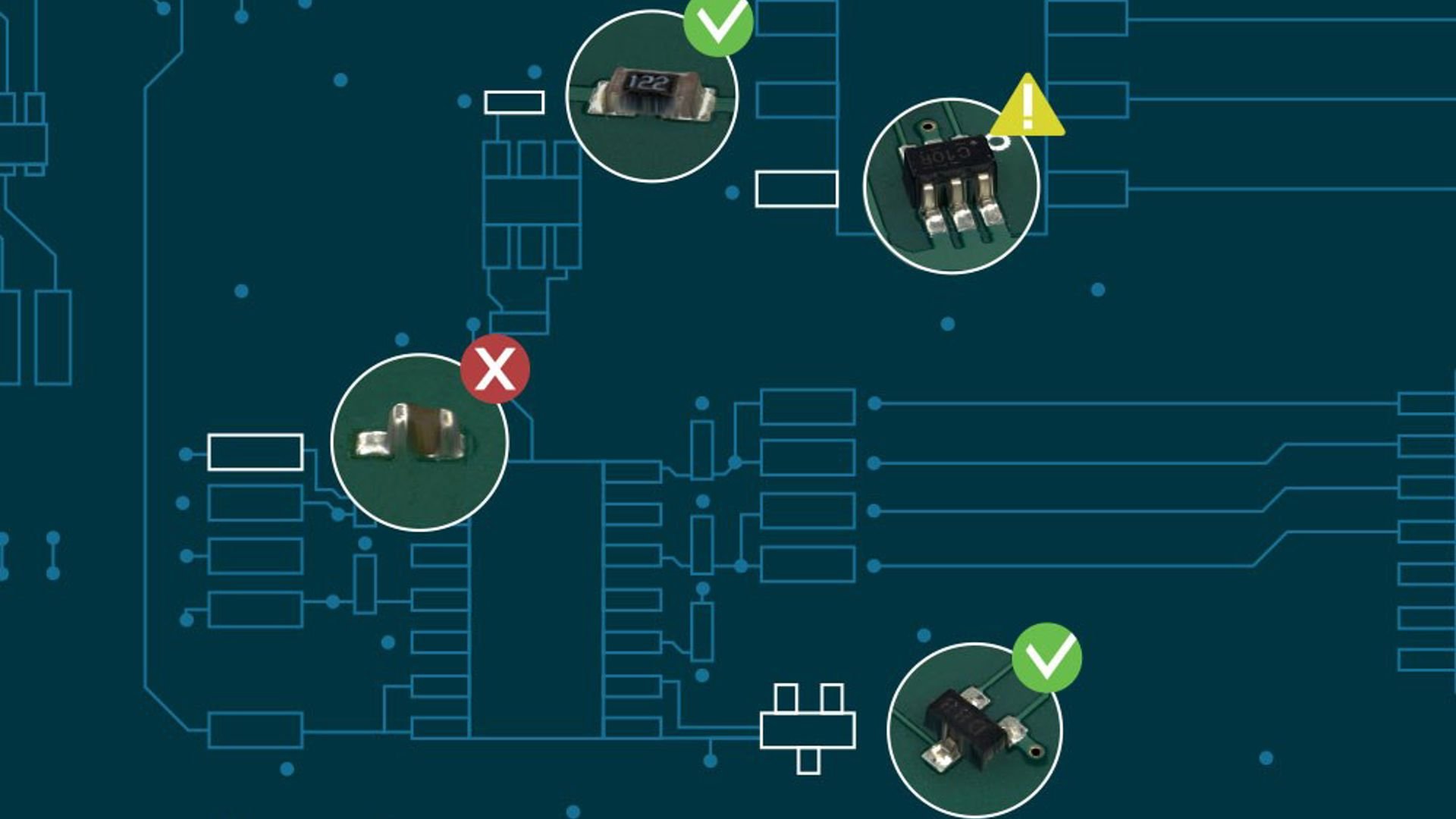

GenI Generative AOI Programming

The industry’s fastest programming — eliminate specialized AOI programming for every new product. Faster NPIs — accelerate introductions with rapid, automated inspection model generation. Plug-and-play metrology — achieve full inspection coverage and traceability with true 3D metrology.

Deep Review for 3D AOI

Accelerate review times. Eliminate the majority of false calls. And automatically improve your defect classification models over time. Deep Review, a new AI-based Automatic Defect Classification system for 3D AOI, makes it possible to apply full test coverage to any product mix without fear of false calls.