Automated optical inspection

Regardless of the takt time of your production line, and regardless of the frequency of your production changes, you are entitled to demand the most efficient AOI technology.

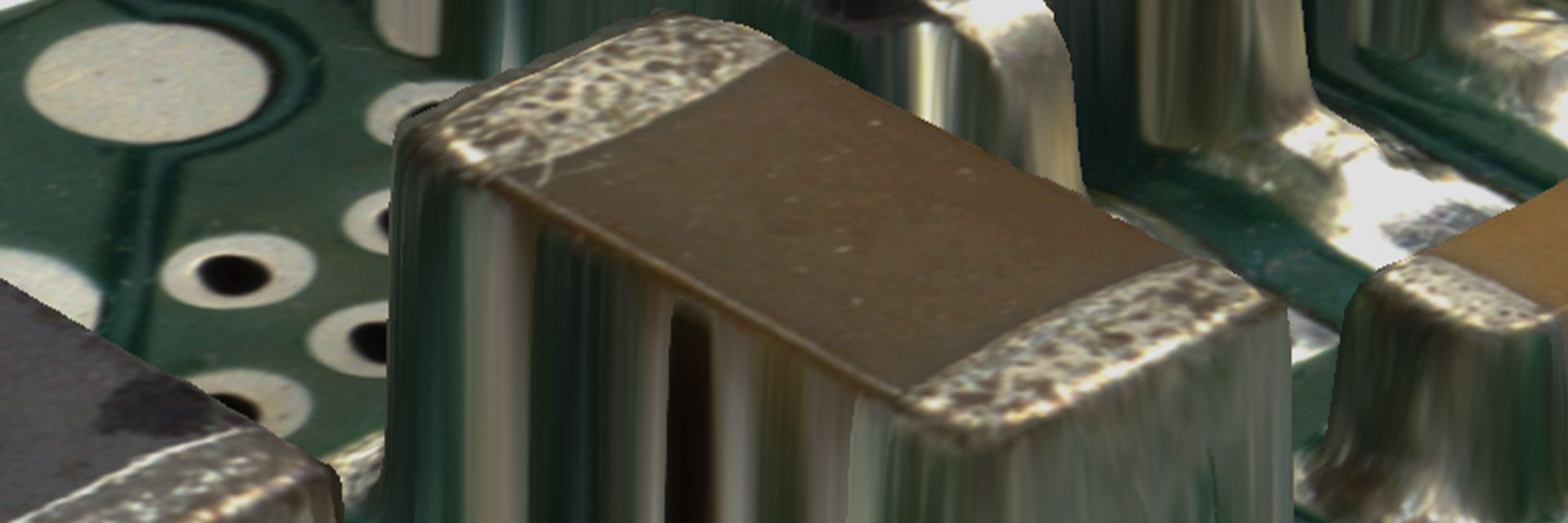

The new MYPro I series 3D AOI meets your requirements by offering one of the most powerful AOI systems on the market now powered by AI-assisted software and featuring a next generation 3D vision technology for faster and sharper processing.