FDI Matelec strengthens its production capacity with a new high-speed Mycronic SMT line

To support their strong growth, FDI Matelec has invested in a new next-generation Mycronic SMT line, the first of its kind in France. This line enables high-speed placement performance speeds, regardless of the type of electronic board being manufactured. Through this technological choice, FDI is significantly enhancing its responsiveness and production capacity to provide its customers with ever higher levels of service performance.

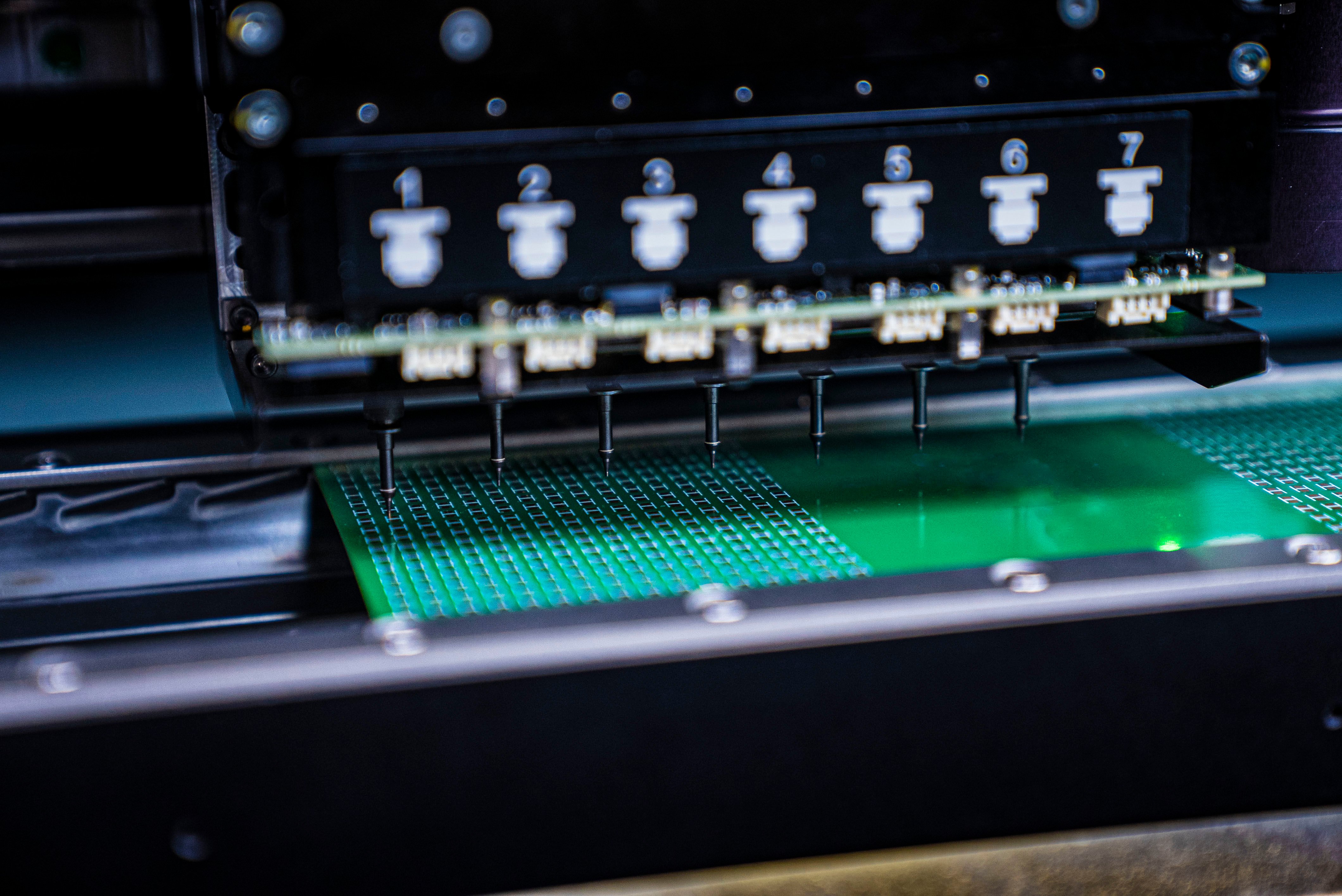

The line consists of three Mycronic MYPro A40DX machines

This offers a placement rate of 177,000 components per hour (CPH).

Equipped with new high-speed MX7 heads, capable of placing 97% of a board’s components at ultra-high speed, they ensure unmatched flexibility on the market while maintaining very high production speeds, even for highly diverse electronic boards

FDI generates €33 million in revenue and is part of the URMET Group. At FDI, customer satisfaction is at the heart of everything we do , it drives our teams and guides all our projects. This commitment has enabled us to sustain steady growth, optimize our industrial processes, and invest regularly in the most innovative technologies,”

Mycronic helps electronic solutions serving the IoT sector

FDI designs and manufactures electronic equipment for access control, intercom, and home automation systems from R&D to industrial production.

The company relies on a team of over 100 engineers, representing around 50% of its workforce, highlighting the importance placed on research and innovation.

Each year, FDI invests heavily in R&D and production resources to offer customers the most advanced technologies.

Annual production includes:

- 1.5 million RFID keys

- 40,000 control units

- 55,000 badge readers

- 13,000 intercom panels

- 800,000 micromodules

To maintain short delivery times while improving productivity and efficiency across its lines, FDI chose Mycronic’s MYPro A40DX machines, the only ones capable of combining speed and flexibility, regardless of the type of electronic board produced.

These machines perfectly meet our performance and agility requirements

Mycronic's new generation of machines for a changing global market

Mycronic is now a world leader in the SMT line market for small and medium series, with several thousand machines installed worldwide. With previous generations, our lines offered placement speeds between 15,000 and 100,000 CPH. But many fast-growing customers wanted to go further, without increasing production staff and while maintaining the same flexibility. That’s how the MYPro A40DX was born.

To design this machine, Mycronic involved R&D engineers based in Japan who had previously worked on ultra-high-speed placement head design for mass production.

The result is exceptional: a machine combining flexibility with mass-production-level speeds , reaching 177,000 CPH with about 97% of components placed using the high-speed head , a world first in this segment.

FDI makes an investment with Mycronic PCB Assembly Solutions geared toward the future

With this strategic investment, FDI Matelec reaffirms its commitment to staying at the forefront of innovation, supporting the development of advanced IoT solutions, and strengthening its industrial competitiveness in both French and international markets.