Press-fit component inspection

Mycronic's solution for press-fit component inspection using 3D AOIMycronic excels in press-fit technology and assembly – demonstrating skilled expertise in handling complex components.

How to detect defects in press-fit component using 3D AOI

Press-fit components offer a solder-free solution for PCB mounting by utilizing a snug mechanical fit. In electronics manufacturing, optical inspection of these components is crucial to ensure the quality, reliability, and performance of the final assembled product. Similar to SMT or THT components, 3D automated optical inspection (AOI) is necessary to detect defects related to press-fit component assembly. However, due to their unique assembly method and physical attributes, the inspection of press-fit components primarily focuses on their mechanical integrity to ensure their geometry remains unaltered during the placement process.

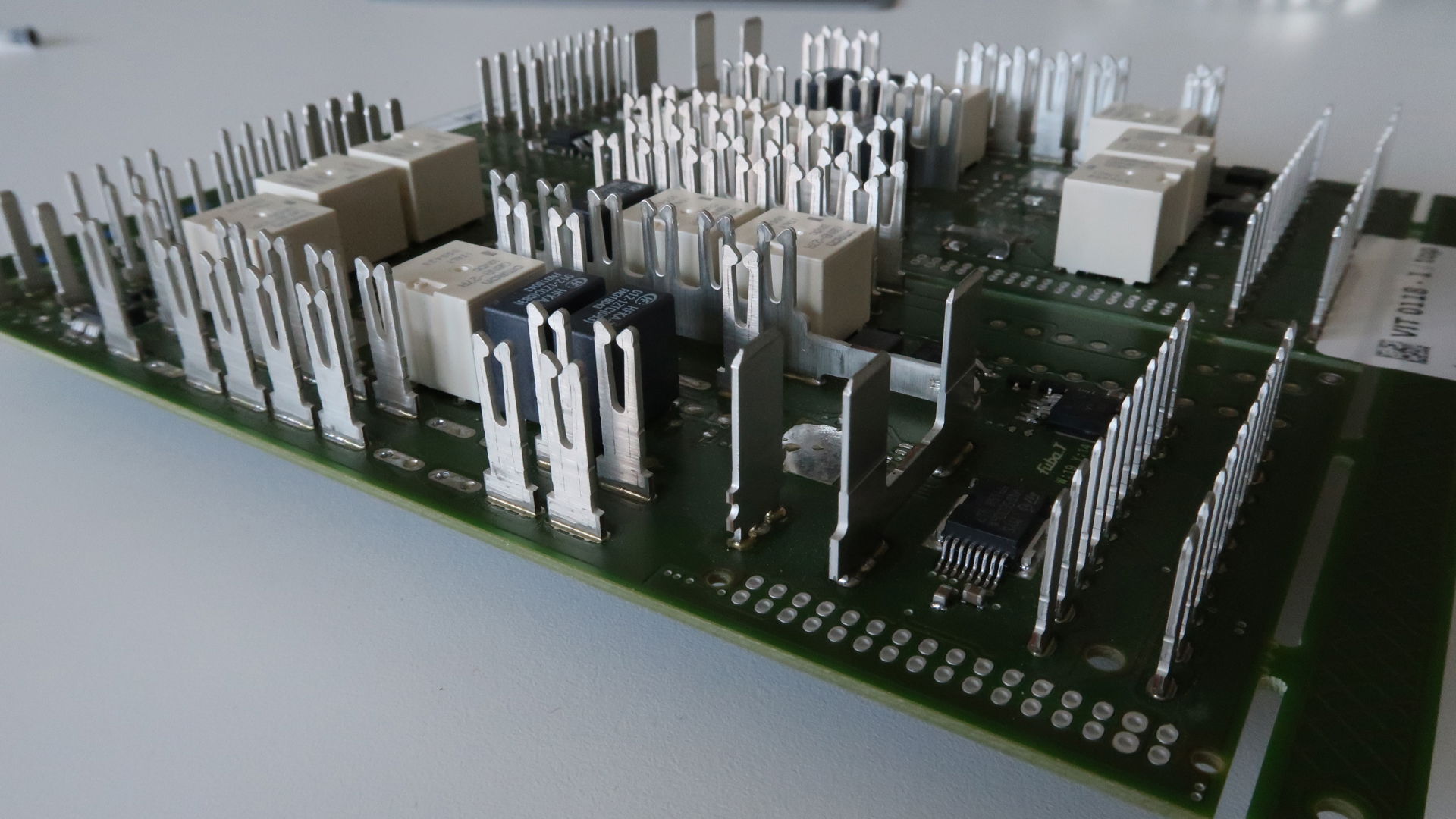

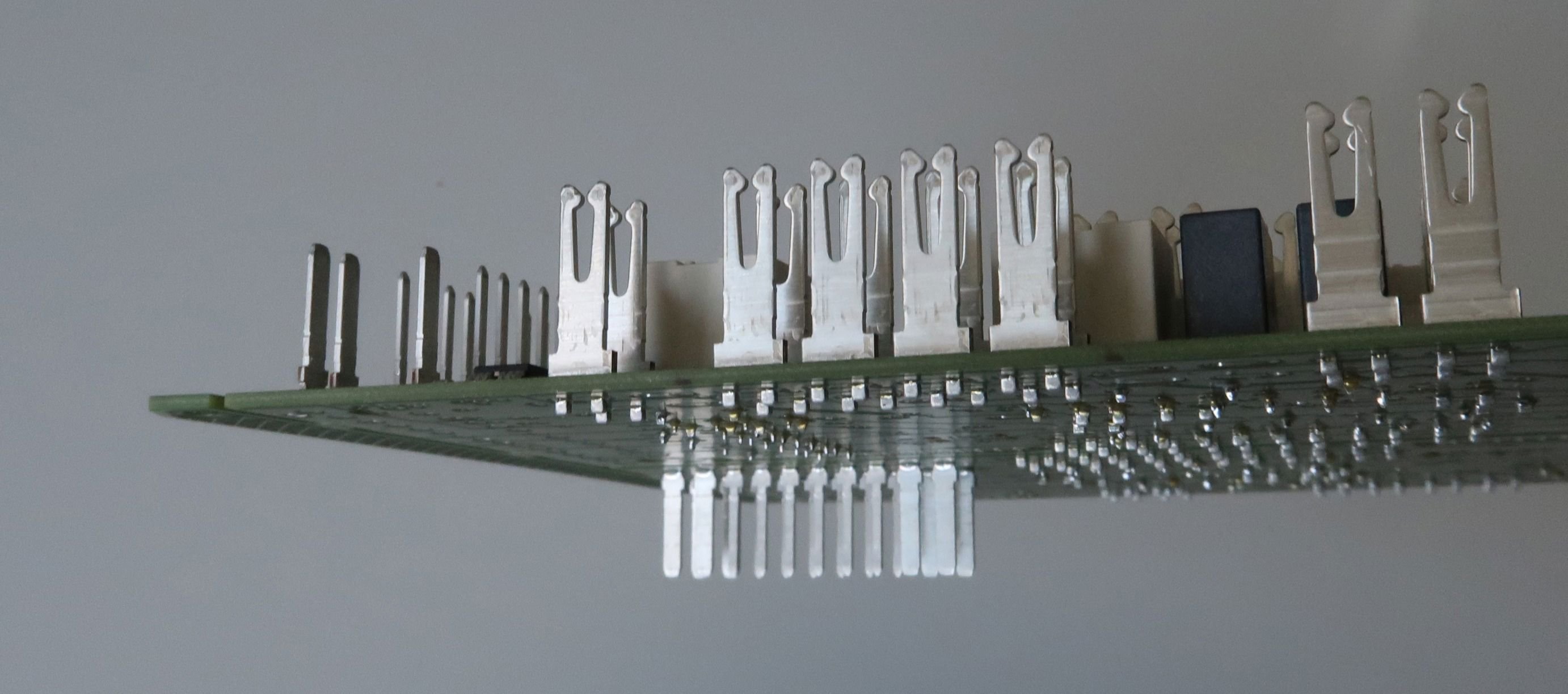

Picture: Fork connectors, IGBT modules, or power elements are common press-fit electronics components.

Mycronic’s MYPro I series 3D AOI features the versatility and accuracy to inspect press-fit components with the same reliability as for any SMT or THT packages. The system can inspect parts up to 20 mm in height, such as solid or compliant pins, or connector modules – just to name a few. "Our 3D AOI system checks for the presence, position, coplanarity, and polarity of the component or pin, ensuring a thorough inspection regardless of the component/pins' physical height," highlights Alexia Vey, Inspection Product Manager. Under certain conditions, parts up to 25 mm high can be inspected.

Inspecting mechanical integrity

The MYPro I series 3D AOI systems are adept at inspecting various press-fit components in their standard configuration. With their extensive test library, these systems can be used to inspect a broad range of packages, connectors, pins, and more. This enables comprehensive 3D test coverage for challenging press-fit components, allowing the detection of pin presence or height, bent pins, base position, and even the distance between pins on fork connectors.

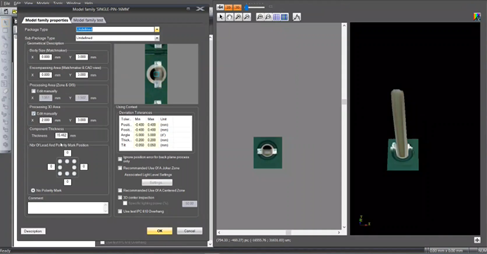

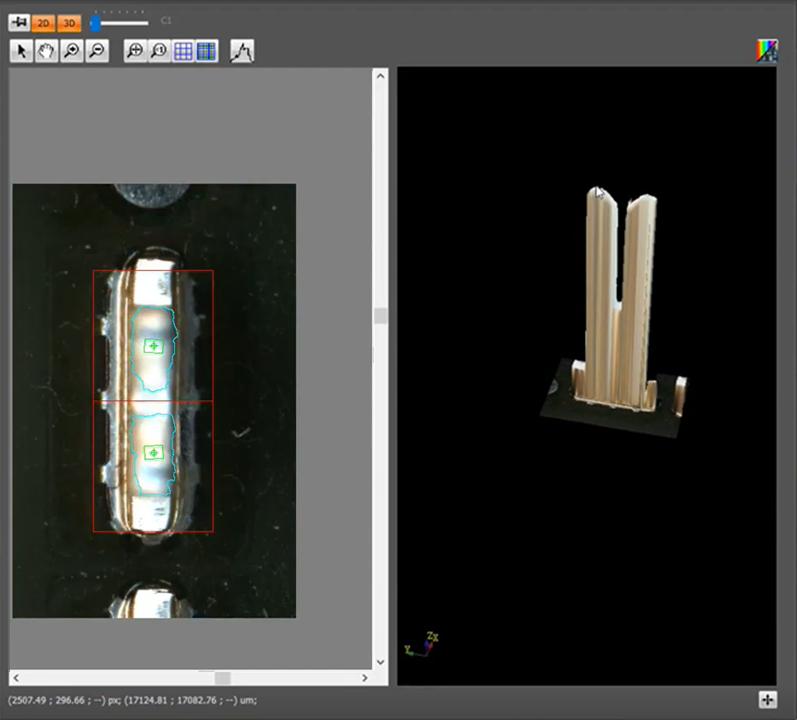

Picture: Configuration of inspection tests for a press-fit pin.

Misaligned or improperly fitted press-fit components can cause excessive stress on both the component and the PCB, leading to long-term reliability issues. Your Mycronic 3D AOI system can be programmed to ensure that components are correctly seated by verifying the press-fit pins are inserted to the appropriate depth without damage. It inspects the height of the pin tips in 3D and measures coplanarity to confirm proper insertion.

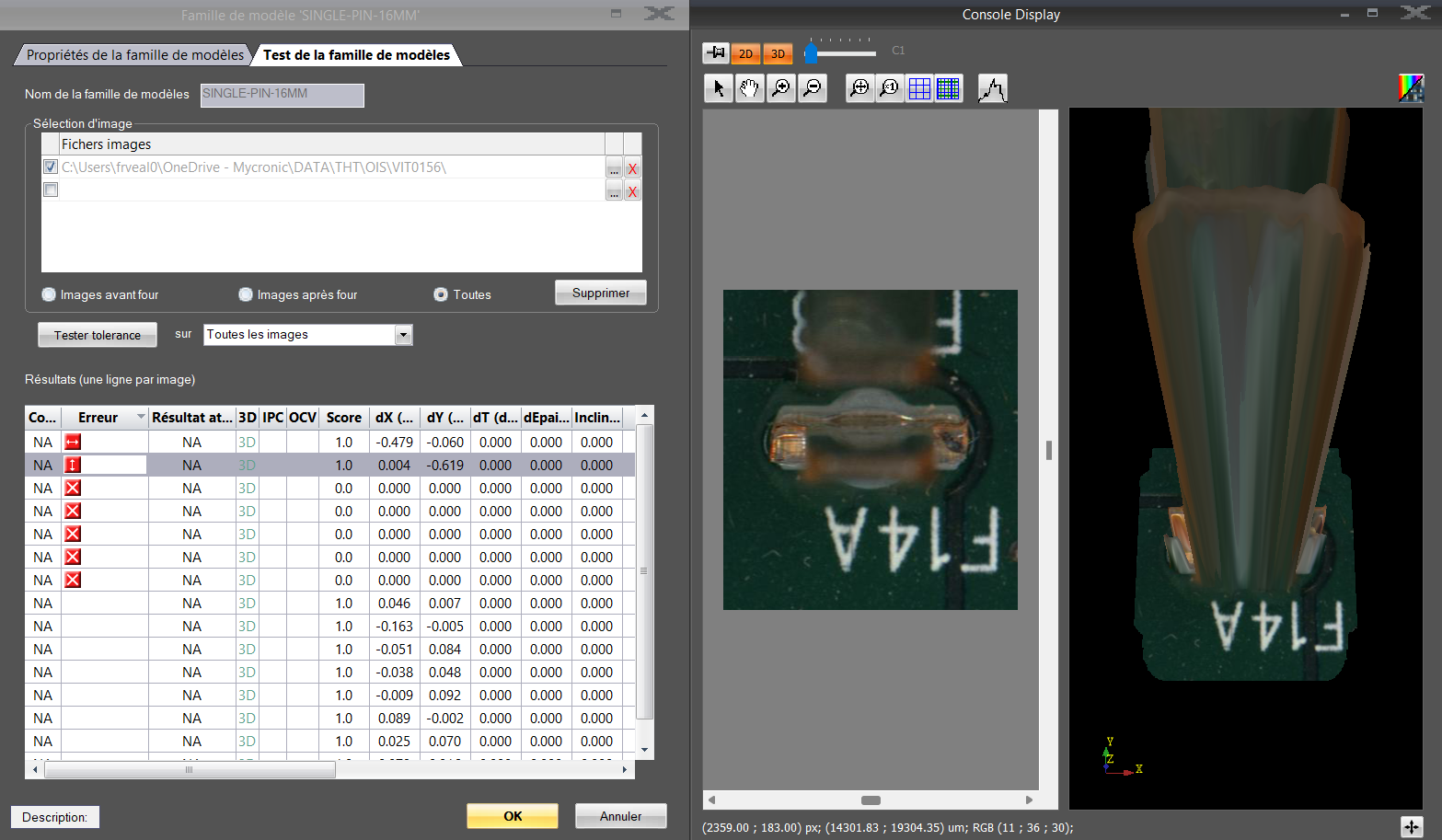

Picture: A bent pin can also be detected.

Fork connector inspection:

To ensure the reliability of fork connectors, it's essential to verify the geometry, ensuring that the fork remains straight and undistorted. Positioning the "3D histogram" tool atop the connector allows the AOI system to automatically perform comprehensive inspections. This includes checking the height and coplanarity of the component, as well as measuring the distance between the fork tines.

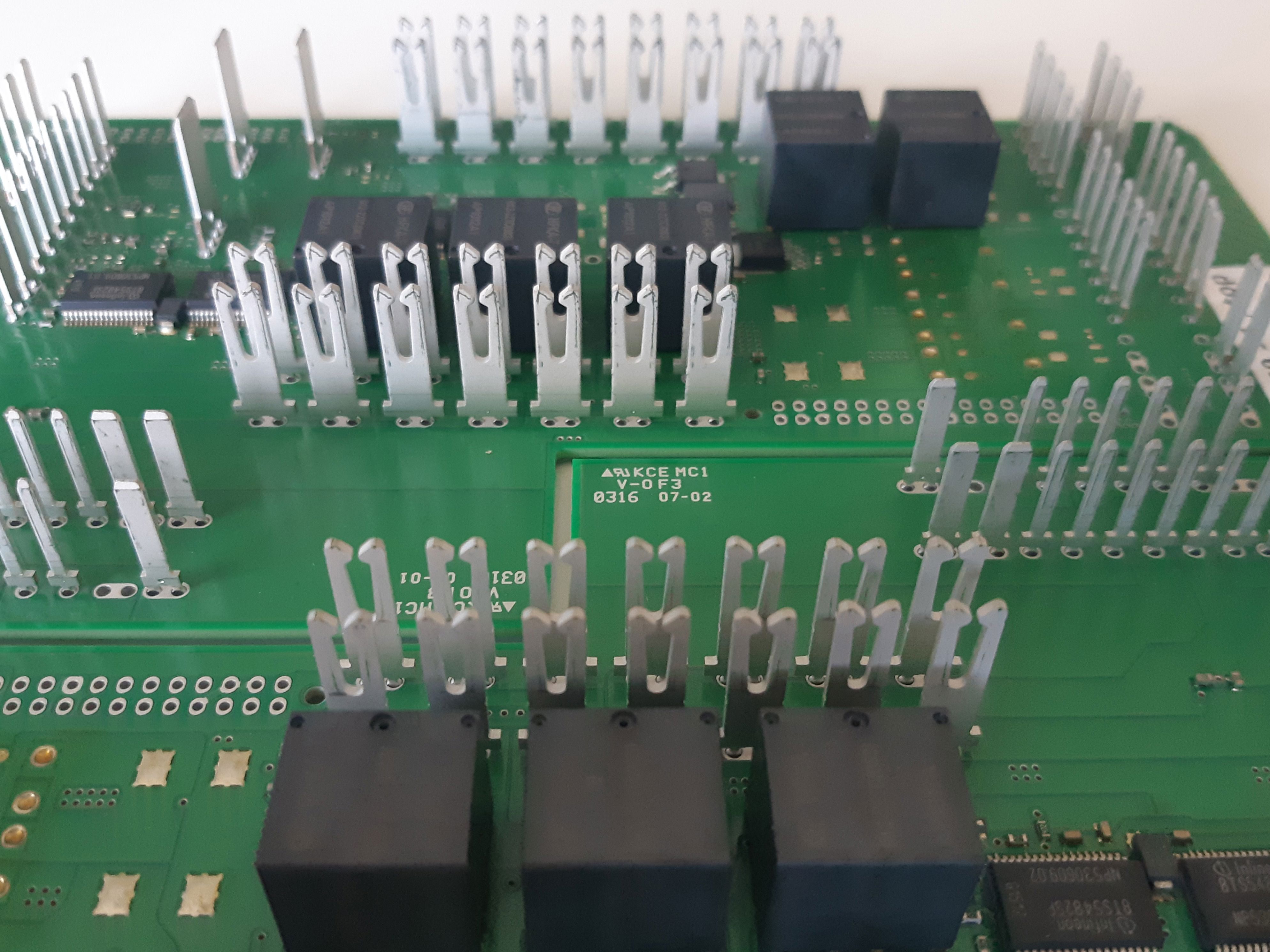

Picture: Press-fit connectors need inspection on both top and bottom sides.

Picture: The MYPro I series 3D AOI enables thorough geometric inspection of fork connectors.

The MYPro I series 3D AOI offers exceptional inspection capabilities for electronics manufacturers, ensuring higher levels of quality and reliability in electronic devices. Engineered to inspect any SMT, THT, or press-fit components or connectors, whether standard or custom, with remarkable accuracy and repeatability, the MYPro I series stands out with its extensive toolbox. This series provides EMSs and OEMs with enhanced inspection capabilities independent of operator skill, contributing to improved product quality and reliability while keeping production costs at a competitive level.

Similar articles you may also like to read: