MYPro I91z - 3D AOI

- AI AI-powered interface for fast and reliable programming

- Fast Up to 30% faster cycle times

- Accurate Best-in-class accuracy

High-performance 3D AOI for heavy duty and thick board inspection

The MYPro I91z 3D AOI is specially designed to handle heavyweight PCBAs up to 15 Kg, special boards with up to 15 mm PCB thickness, or PCBAs on carrier. For reference, MYPro I91z is operated by PCBA’s manufacturers for telecom infrastructures, data centers or high-voltage power management.

Geared with the new Iris™ 3D vision technology, it benefits from up to 30% faster processing time while doubling up on pixel resolution. The result is a real breakthrough in inspection cycle times keeping pace with the most demanding production lines in the industry, and an increased test coverage with the ability to inspect 008004 (0201 metric) component packages.

Industry-leading performance and production stability

MYPro I91z brings 3D AOI for high-mix production

MYPro I50Xz’s comprehensive test coverage enables 3D inspection of all SMT, THT and press-fit components, both at the pre-reflow and post-reflow stages.

MYPro I91z is the industry-leader for performance and production stability, here's why:

The MYPro I series offers best-in-class accuracy and repeatability in X, Y, Z and Theta for efficient process control. The unique combination of sub-pixel geometric pattern matching technology, proprietary 3D algorithms and unique warpage and distortion compensation leads to superior critical measurement capabilities.

- Vectoral imaging pattern matching.

- +/- 5 mm warpage compensation with full Z accuracy.

- 3.5 μm X,Y resolution with sub-pixel technology

- Constant 1 µm Z resolution, from -5 up to 20 mm in altitude

MYPro I91z offers all-in-one inspection capabilities

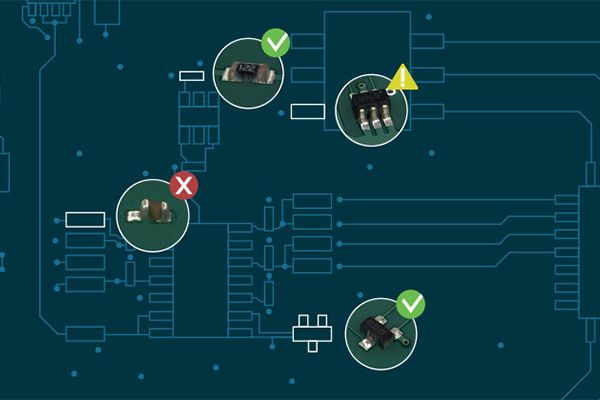

With full test coverage, the MYPro I series measures the component body, leads, and solder joints with the utmost accuracy to catch any type of defects.

Its comprehensive toolbox of ready-to-use 2D and 3D inspection tests allows the MYPro I series to inspect not only all SMT components, but also through-hole components, press-fit components, connectors of all types and shapes, and any new packages.

The board geometry and relative positions of components, pins, or connectors can also be inspected with metrological precision to further expand your test coverage and production quality.

MYPro I91z is a fully integrated process control with the following:

MYPro Link

MYPro Link, Mycronic’s award-winning web-based process control software suite, puts the benefits of inspection data correlation into real-time production. All so you can monitor your line performance over time or at a glance and get to the root cause of every defect in just a few clicks.

MYPro Analyze

Monitor your process in real time with MYPro Analyze: accurate production data help you optimize your performance and give you meaningful information to further improve and maximize first-pass yield.

For heavy-weight boards up to 15 kg

MYPro I91z is designed to handle and inspect heavy-duty heavy-weight boards up to 15 kg. In terms of PCB size, it can process large PCBAs up to 533 x 609 mm (21 x 24”).