MYPro I50Xz - 3D AOI

- AI AI-powered interface for fast and reliable programming

- Accurate High accuracy and production stability

- All-in-one All-in-one inspection capabilities

The MYPro 150Xz bring high-performance 3D AOI for high-mix production

The MYPro I50Xz brings high-performance 3D AOI within the reach of high-mix electronics producers, thanks to the extreme versatility of its inspection capabilities together with

-

MYWizard, our next-level AI-based programming interface that reduces programming time by up to 30%.

-

Gen I™, Generative AOI Programming, you can create production-ready 3D inspection programs in minutes – directly from pick-and-place and scan data. No model creation. No library management. No delays.

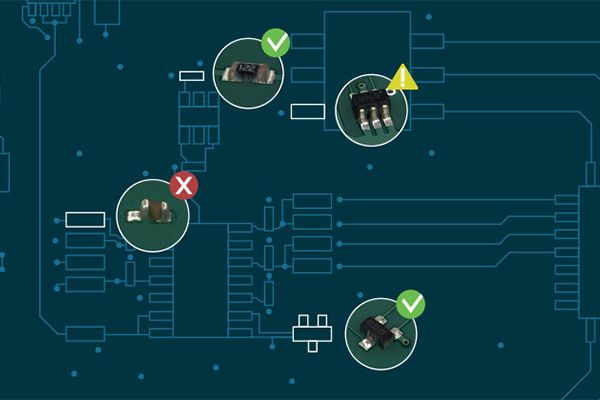

MYPro I50Xz’s comprehensive test coverage enables 3D inspection of all SMT, THT and press-fit components, both at the pre-reflow and post-reflow stages.

Discover the all-in-one high-perfomance inspection capabilites.

MYPro 150Xz brings 3D AOI for high-mix production

MYPro I50Xz’s comprehensive test coverage enables 3D inspection of all SMT, THT and press-fit components, both at the pre-reflow and post-reflow stages.

MYPro 150Xz is the industry-leader for performance and production stability, here's why:

The MYPro I series offers best-in-class accuracy and repeatability in X, Y, Z and Theta for efficient process control. The unique combination of sub-pixel geometric pattern matching technology, proprietary 3D algorithms and unique warpage and distortion compensation leads to superior critical measurement capabilities.

- Vectoral imaging pattern matching.

- +/- 5 mm warpage compensation with full Z accuracy.

- 3.5 μm X,Y resolution with sub-pixel technology

- Constant 1 µm Z resolution, from -5 up to 20 mm in altitude

MYPro 150Xz offers all-in-one inspection capabilities

With full test coverage, the MYPro I series measures the component body, leads, and solder joints with the utmost accuracy to catch any type of defects.

Its comprehensive toolbox of ready-to-use 2D and 3D inspection tests allows the MYPro I series to inspect not only all SMT components, but also through-hole components, press-fit components, connectors of all types and shapes, and any new packages.

The board geometry and relative positions of components, pins, or connectors can also be inspected with metrological precision to further expand your test coverage and production quality.

MYPro 150Xz is a fully integrated process control with the following:

MYPro Link

MYPro Link, Mycronic’s award-winning web-based process control software suite, puts the benefits of inspection data correlation into real-time production. All so you can monitor your line performance over time or at a glance and get to the root cause of every defect in just a few clicks.

MYPro Analyze

Monitor your process in real time with MYPro Analyze: accurate production data help you optimize your performance and give you meaningful information to further improve and maximize first-pass yield.

Contact us to discover the power of AOI for any environment.