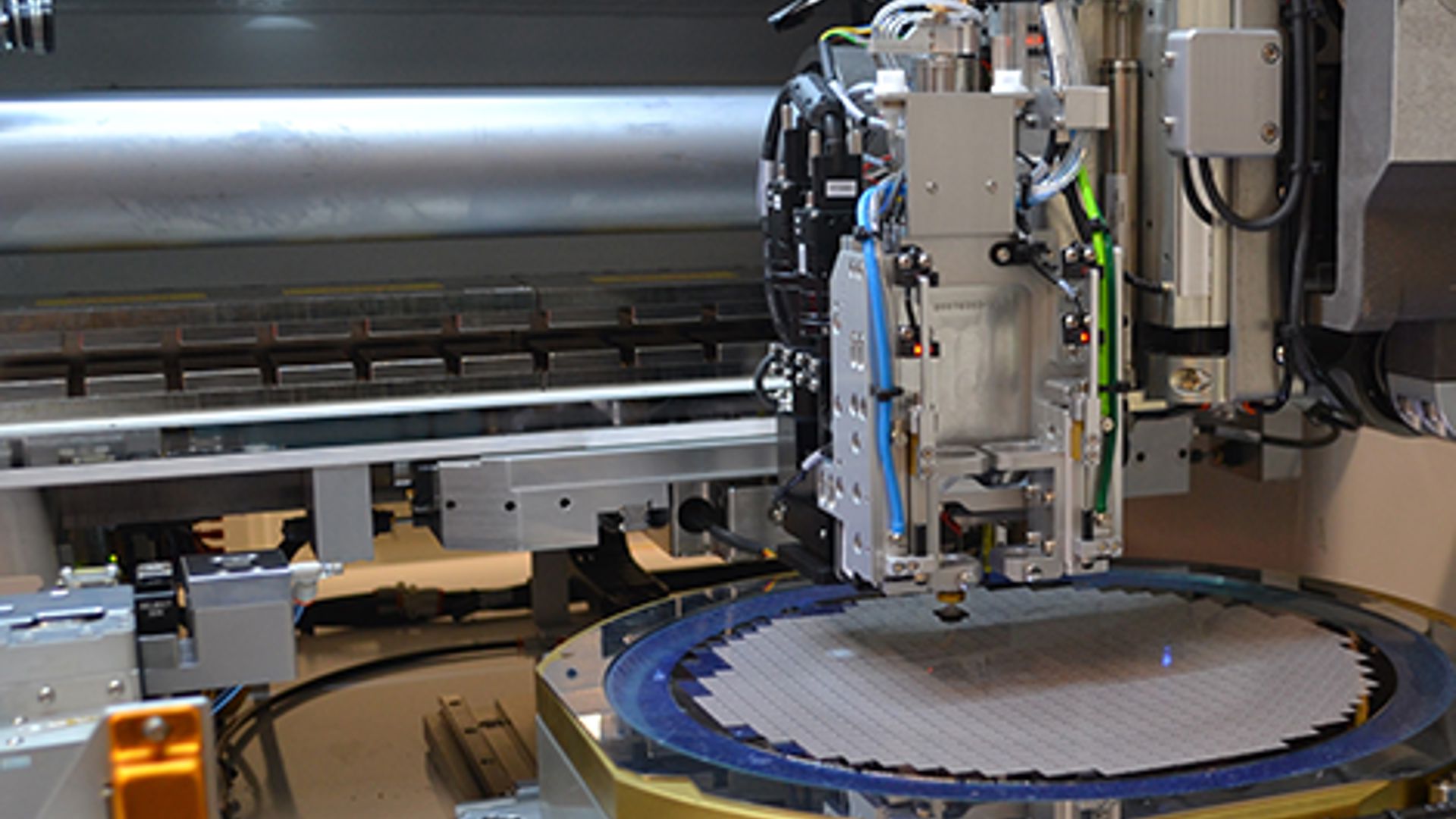

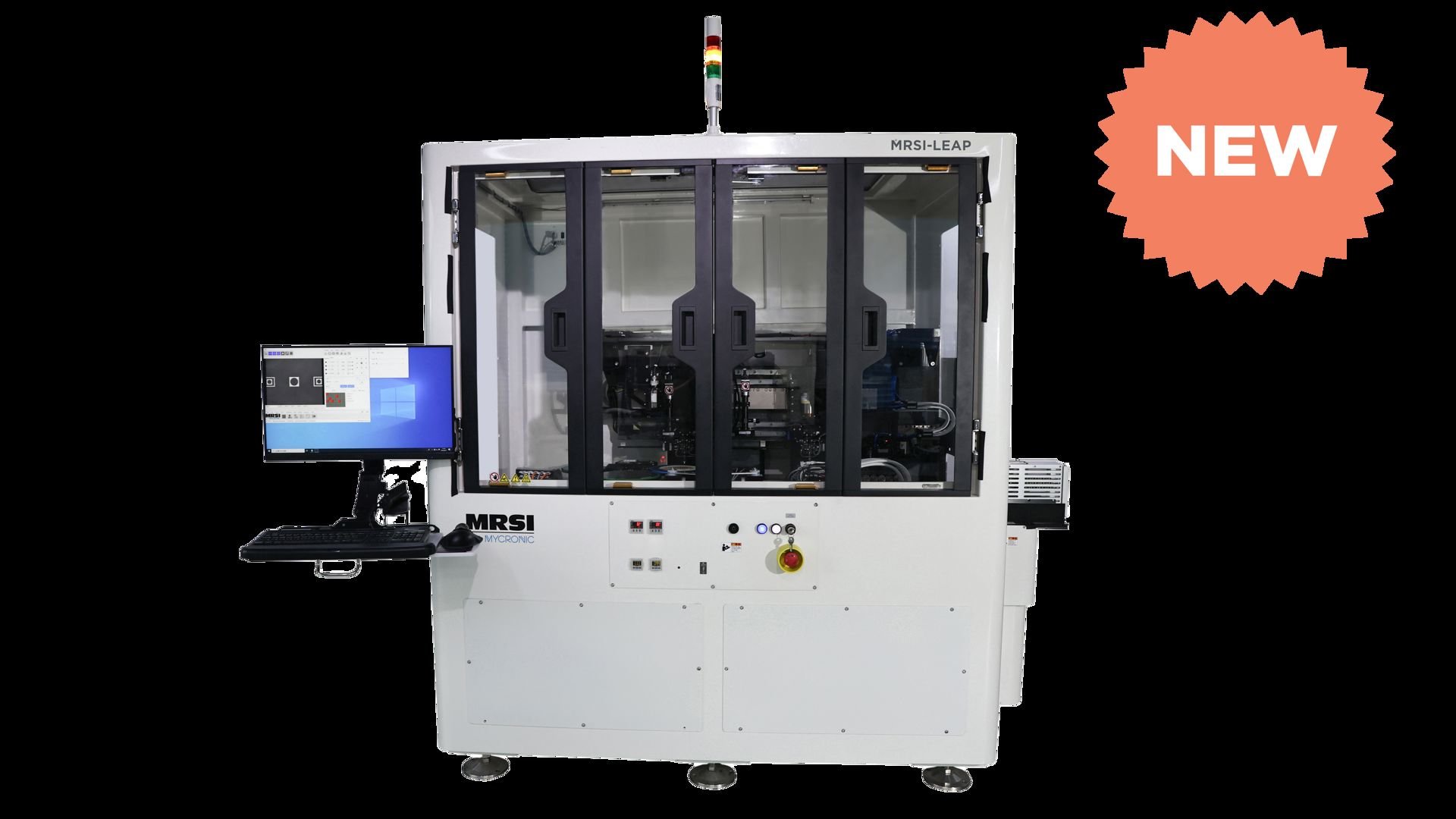

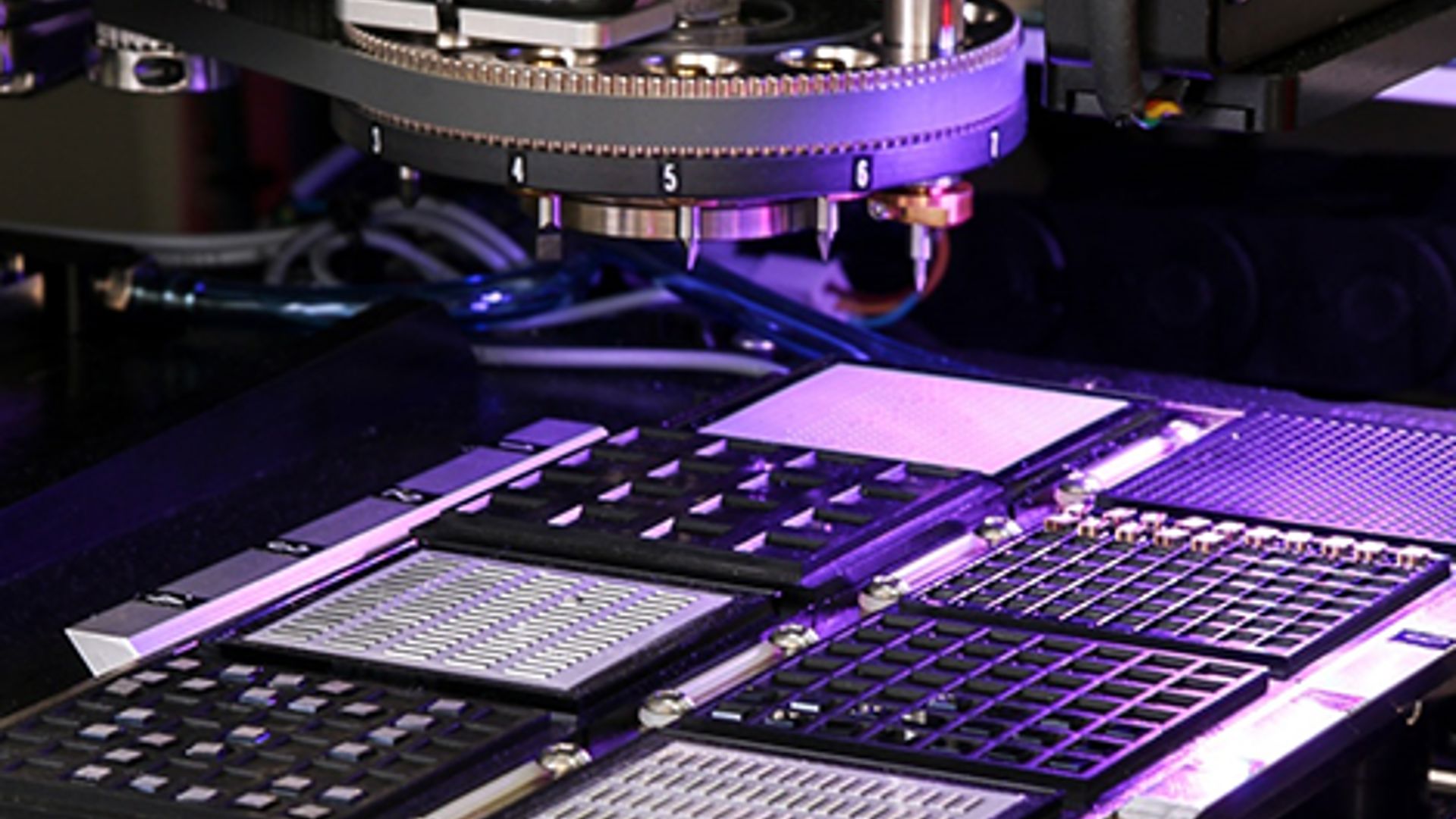

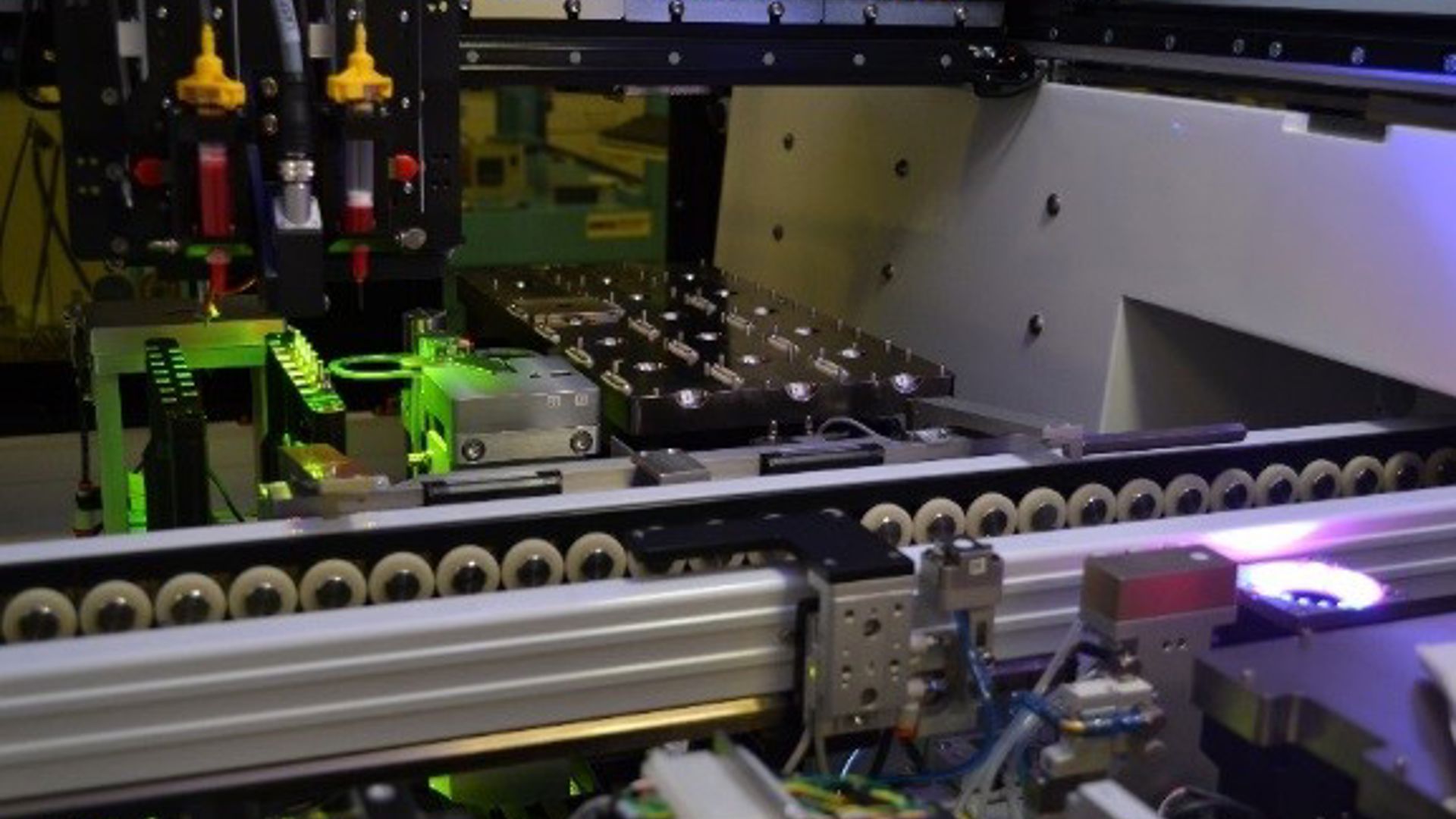

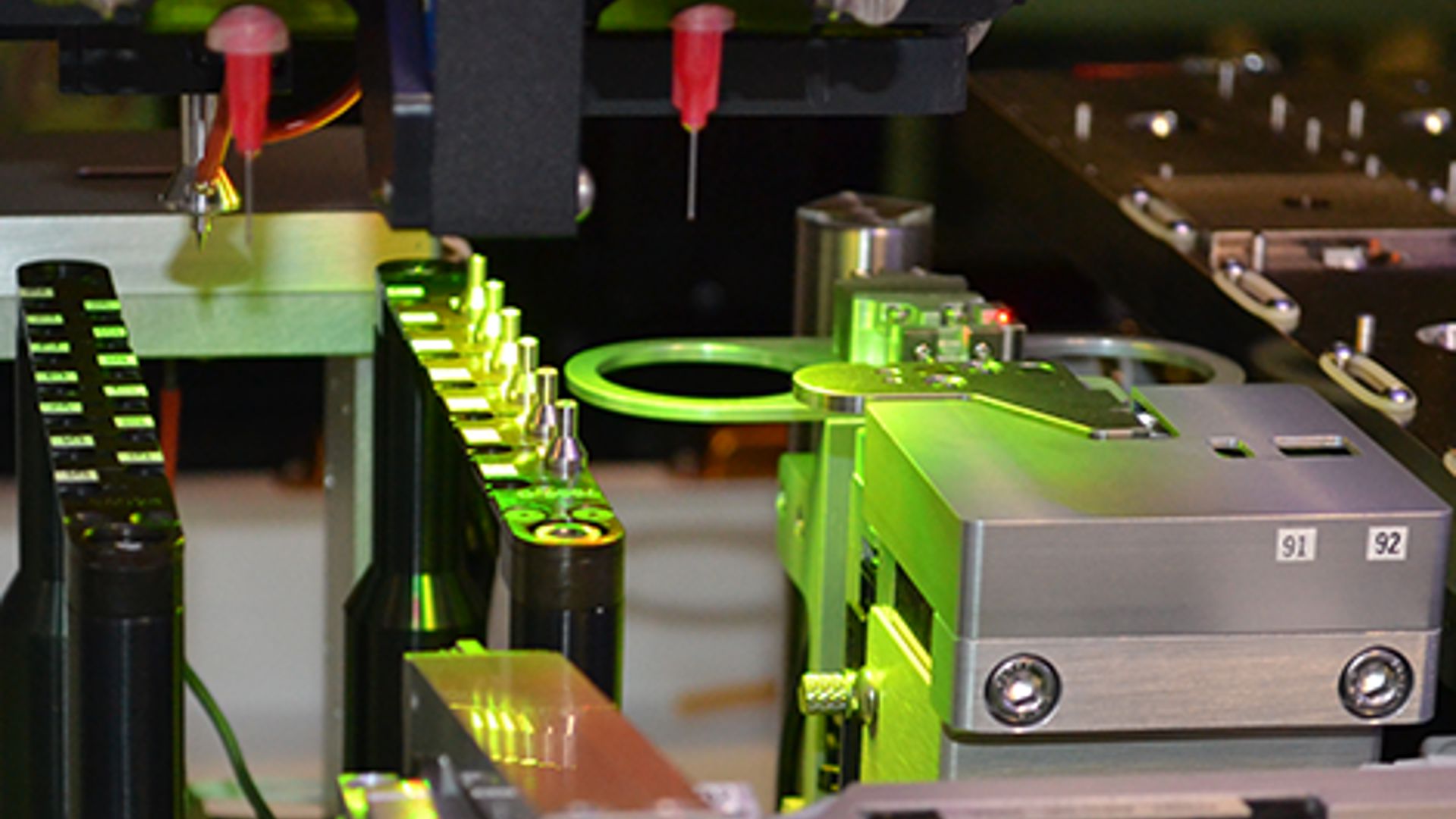

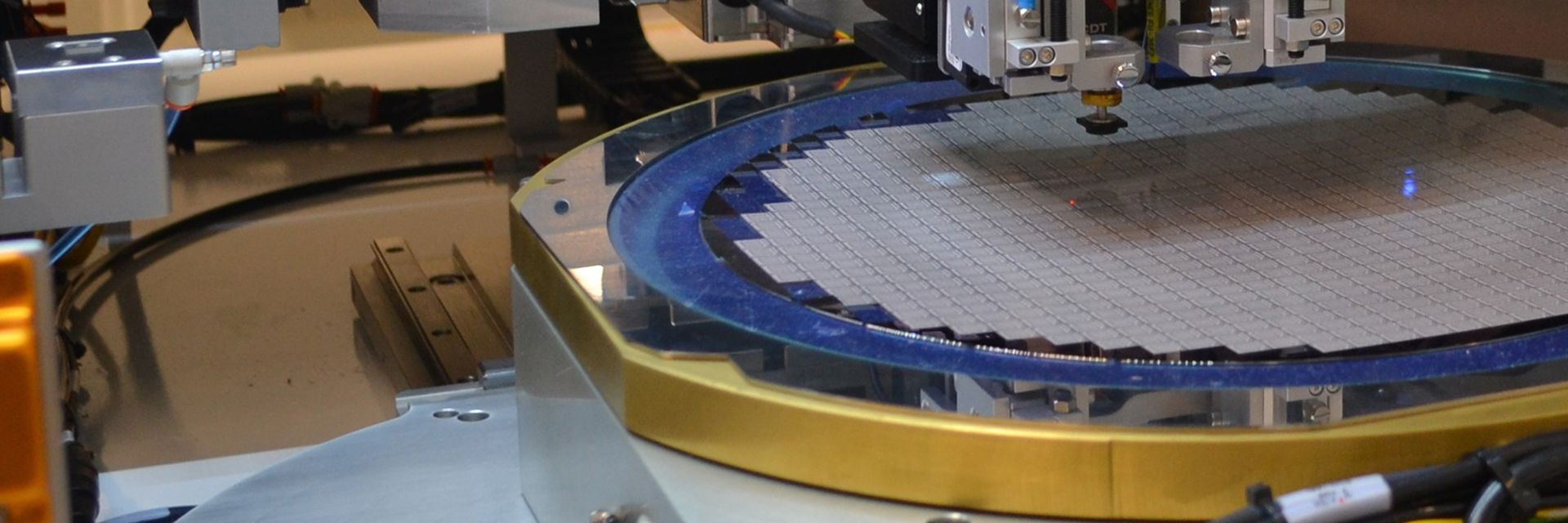

Our Family of Products

MRSI values our customers, and our top priority is meeting our customers needs down to the finest detail. We are proud that all of our products are industry-leading, with superior flexibility, ultra-high-accuracy, and multiple process options. Our product’s value is further illustrated by our 40+ years of experience in the industry in tandem with our 24/7 reliable field operations.