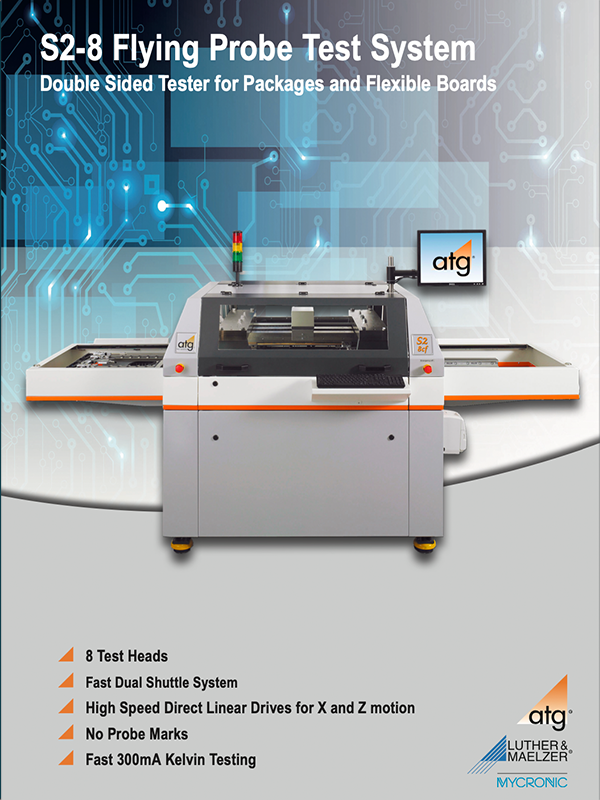

S2-8 / S2-8 plus

S2-8 / S2-8 plus

- Productivity Semi-automatic double shuttle system

- Stability 8 ultra-light carbon test heads with air bearings

- Flexibility Layup table for advanced flex product handling

Description

The Substrate product line is characterized by outstanding test head technology. Linear motor drives in combination with ceramic air bearings provide exceptional speed and accuracy.

The S2 testers are equipped with a dual shuttle system allowing parallelized testing and loading/unloading, maximizing machine utilization. The standard S2 is equipped with 8 test heads and has a test area of 12" x 12.2"

Key benefits

- Catering to the needs of substrate testing

The system combines accuracy and low witness marks with high thruput. The semi-automatic dual shuttle system concept gives best system utilization.

Specification

|

8 test heads |

|

|

Ceramic air bearings for ultra-precise and sensitive contacting |

|

|

High-resolution cameras with 6 or 3 microns per pixel (standard version / plus version) |

|

|

Max. test area mode |

610 mm x 305 mm (24"x 12.2") |

|

Max. product size |

610 mm x 330 mm (24" x 13") |

|

Test speed |

up to 200 TP/sec (depending on test method) |

|

Smallest pad/pitch size |

plus version 15 µm (0.6 mil)/ 30 µm (1.2 mil) (using max. test area 11.8” x 12.2”) standard version: 25 µm (1.0 mil) / 50 µm (2.0 mil) using max. test area 11.8" x 12.2") |

|

Smallest pad/pitch size |

25 µm (1 mil)/50 µm (2.0 mil) (using max. test area 24.0” x 12.2”) |

|

Dual shuttle for faster product exchange |

|

|

No visible probe marks (using Micro Probes) |

|

|

Options |

High-speed Kelvin 4 wire test up to 300 mA, Embedded component test, 1000 V high voltage |

Services

Contact

Do you have a question?