Comparison of Speed and Throughput

In the realm of Contract Manufacturing (CM), selecting the right equipment is a nuanced decision shaped by a myriad of variables. These factors are essential for enabling CMs to bid competitively and to deliver high-quality products efficiently. A CM routinely encounters a diverse array of assembly projects, ranging from low-volume runs of fewer than a hundred units, to medium-scale batches, and extending all the way to high-volume production, where original equipment manufacturers (OEMs) may require thousands—or even tens of thousands—of units to be assembled. The ability to adapt to this spectrum of production demands hinges on making informed choices about manufacturing equipment and process capability.

When choosing equipment, it is essential to look at two key factors: speed and throughput. Although they might seem interchangeable, these terms actually have unique definitions in micro assembly, especially for contract manufacturers dealing with many types of technologies. Each metric is important but serves a different purpose. The explanation below will clarify how each one plays its own role.

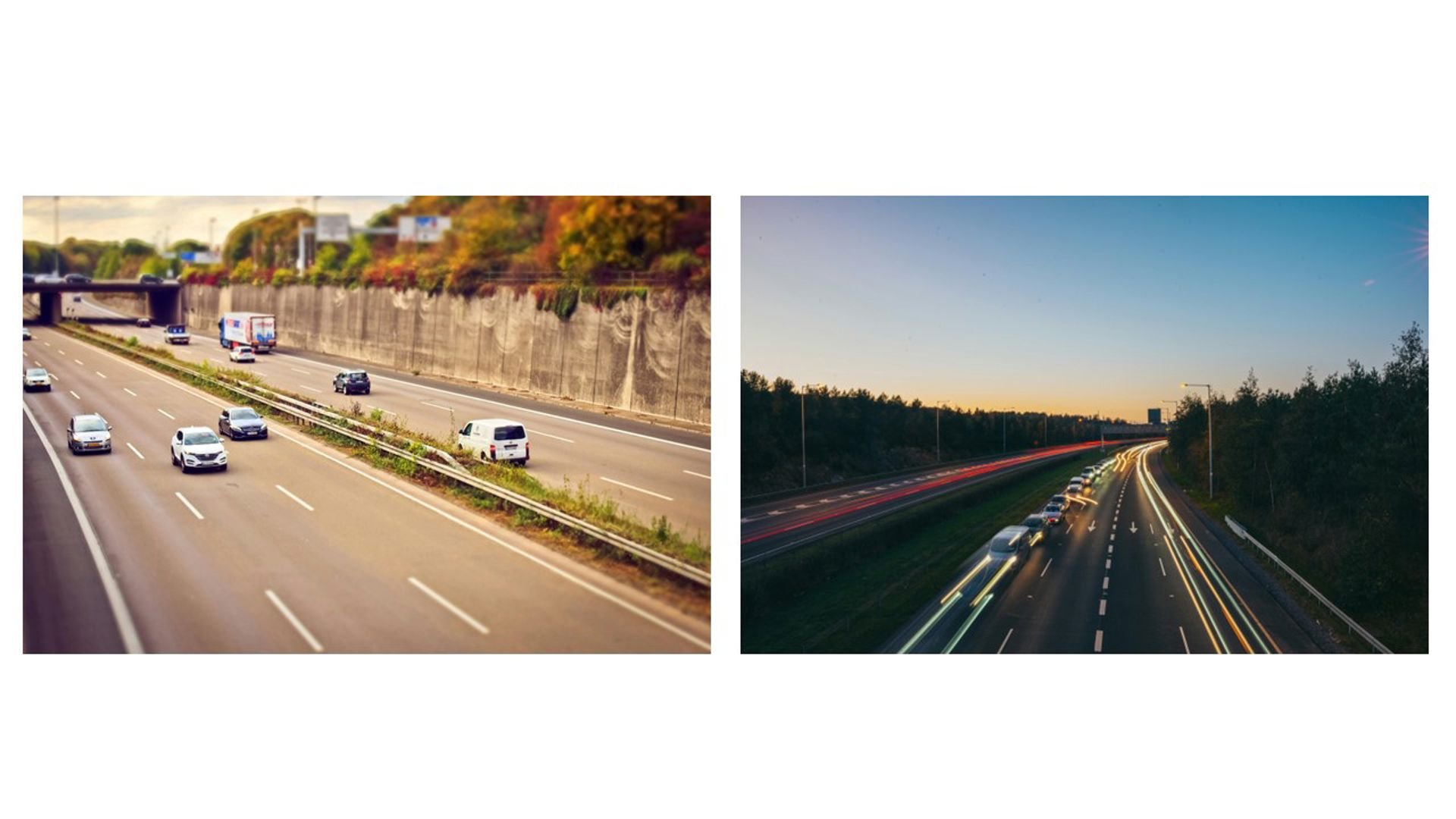

In a manufacturing environment, speed and throughput are often used interchangeably when referring to measurements such as PPH (Parts per Hour) or UPH (Units per Hour). Speed typically refers to how quickly a machine operates, such as a die bonder, picking and placing and often times in-situ bonding to a substrate, or dispensing a medium to designated areas. Throughput generally indicates the amount of product that an assembly line or cell can produce, with a focus on completed products ready for testing. Think of it this way – Speed on a freeway with more lanes allows for more cars to travel. Hence, multiple machines provide more products. Using the same freeway analogy, throughput is the amount of product that can be successfully assembled within a given period.

In the world of contract manufacturing, it is essential to recognize that speed and throughput are fundamentally distinct—especially when process flexibility is at stake. For a CM, facing dozens of ever-changing product builds, each with unique assembly demands, the difference matters. When it comes to die bonding, speed simply is not synonymous with throughput. Let me be clear—these two metrics are separate and must be understood as such to unlock true manufacturing agility.

High precision die bonding is a discipline reserved for leaders in advanced manufacturing—those who understand that success in contract manufacturing depends as much on agility as on technical excellence. In sectors like fiber optics, LEDs, and smart automotive solutions, flexibility is not a luxury; it is a necessity. The role of speed here cannot be overstated. Every minute spent retooling for a new product build is either a cost or a competitive advantage. Time to market is the decisive factor in winning contracts, which means manufacturers must choose partners who can deliver quality at pace.

This is exactly where our die bonding solutions excel. We have engineered our platforms for rapid changeover, enabling our customers to transition seamlessly from one product to the next—often in a matter of minutes rather than hours. This capability is not an afterthought but a core design philosophy that empowers contract manufacturers to maximize uptime, minimize costs, and consistently outpace the competition.

Switching from one process to another process can often require several hours or even up to two days, especially when maintaining bonding accuracy greater than 1µm. The equipment described enables this transition in approximately 15 minutes. This rapid changeover allows contract manufacturers to efficiently handle various production volumes with reduced downtime, potentially lowering operational costs and supporting quicker delivery timelines for their customers.

While some machines may achieve higher throughput than MRSI in repetitive production scenarios, our equipment excels in flexibility and rapid changeovers. In these areas, we offer solutions that are unmatched within the industry.

Ready to unlock true die bonding flexibility and take your manufacturing operations to the next level? Don’t hesitate—contact us today. Our team stands ready to help you achieve unmatched agility and performance in your assembly processes. Let’s build your competitive edge together.