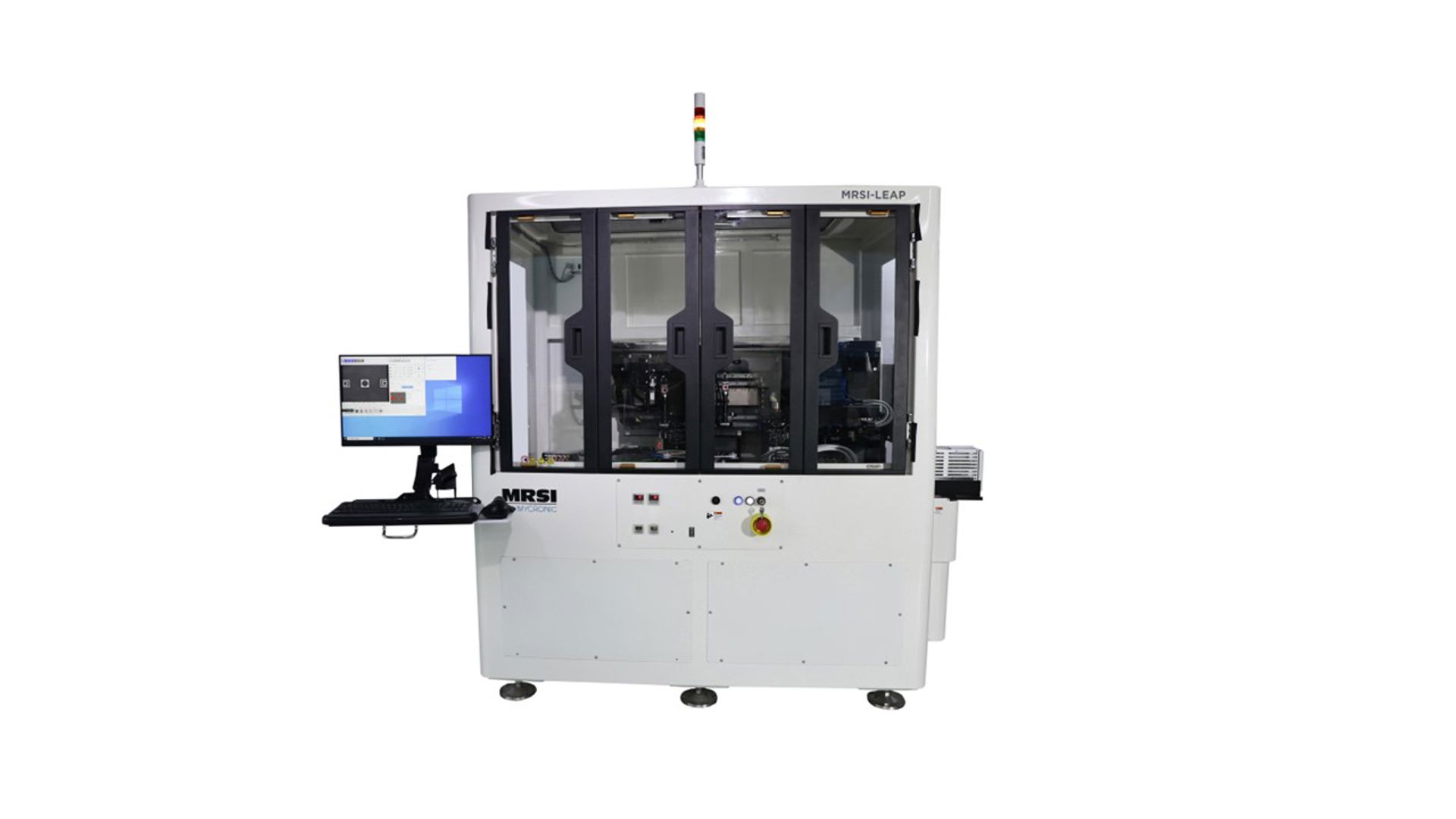

MRSI-LEAP Ultra-High-Speed Die Bonders: Revolutionizing High-Volume Manufacturing

Ultra-high-speed die bonding technology is pivotal in modern manufacturing, particularly for optical modules production. The MRSI-LEAP Ultra-High-Speed Die Bonders exemplify this advancement, offering unmatched efficiency, precision and flexibility.

High-Efficiency and Throughput Capacity

The MRSI-LEAP is engineered to deliver high throughput, making them an invaluable asset in any high-volume manufacturing setting. With a pick-and-place throughput that exceeds 1,000 units per hour (UPH), the MRSI-LEAP ensures that productivity remains consistently high. This remarkable throughput is achieved without compromising the machine’s stability or precision that MRSI is renowned for.

Precision and Stability

The MRSI-LEAP is very precise and stable. This level of precision is essential for applications that demand meticulous alignment and placement, particularly in the production of optical modules where even the slightest deviation can compromise performance. The consistency of the MRSI-LEAP ensures long-term reliability, making it a trusted choice for manufacturers who prioritize precision and yield.

Versatile Material Handling and Tool Changes

The MRSI-LEAP supports multiple wafer inputs and automatic tool changes, accommodating various manufacturing requirements. Material input methods include wafers, Waffle packs, Gel-Pak®, and customized fixtures. This flexibility is integral to the machine’s design, allowing it to seamlessly integrate into diverse production environments. The built-in conveyor system is designed for the boat loader & multiple cassette inputs, capable of automatically transporting high capacity die carriers.

Applications and Features

The MRSI-LEAP is specifically designed for the high-volume manufacturing of optical modules. Its applications include Chip-on-Carrier (CoC), Chip-on-Submount (CoS), and Chip-on-Baseplate (CoB) assemblies, all utilizing epoxy stamping die bonding. Additional processes such as flip-chip bonding, UV epoxy dispensing, in-situ UV curing, and wafer-level packaging are available options, further enhancing the machine’s versatility.

Customer Value

The MRSI-LEAP High-Speed Die Bonders provide industry-leading throughput and ultra-high accuracy, making them a cornerstone of high-volume manufacturing. The pick-and-place process capable of achieving over 1,000 units per hour (UPH) ensures that production targets are consistently met. The machine’s accuracy guarantees long-term stability and precision, essential for maintaining the high quality of manufactured components.

In conclusion, the MRSI-LEAP High-Speed Die Bonders represent a significant leap forward in the field of high-volume manufacturing. With its exceptional efficiency, precision, and versatility, it is poised to revolutionize the production of optical modules and other high-precision components. MRSI-LEAP’s user-friendly interface, robust support infrastructure, and extensive configuration options make it an indispensable tool for manufacturers seeking to enhance their production capabilities and achieve new levels of excellence.