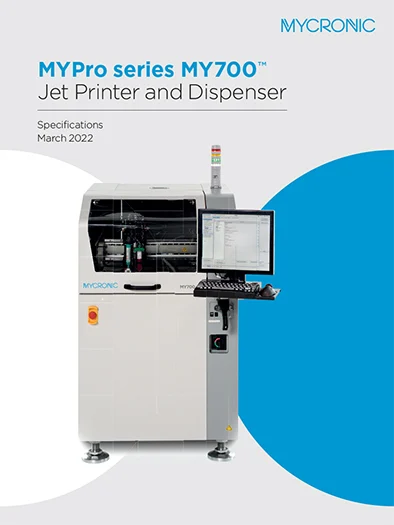

MY700JX jet printer and dispenser

MY700JX jet printer and dispenser

- Combined process steps Reduce costs and line length.

- Flexible and productive Dual-lane and dual-head capabilities increase throughput.

- Fast cycle times Reduced non-jetting time and board buffering.

The all-in-one solder paste and assembly fluid solution

In mixed production environments, the MY700JX allows you to combine operator-independent solder paste jet printing with high-speed jet dispensing of adhesives, UV materials, epoxies and more. With both capabilities in the same machine and process step, there’s virtually no board, package or component you can’t handle.

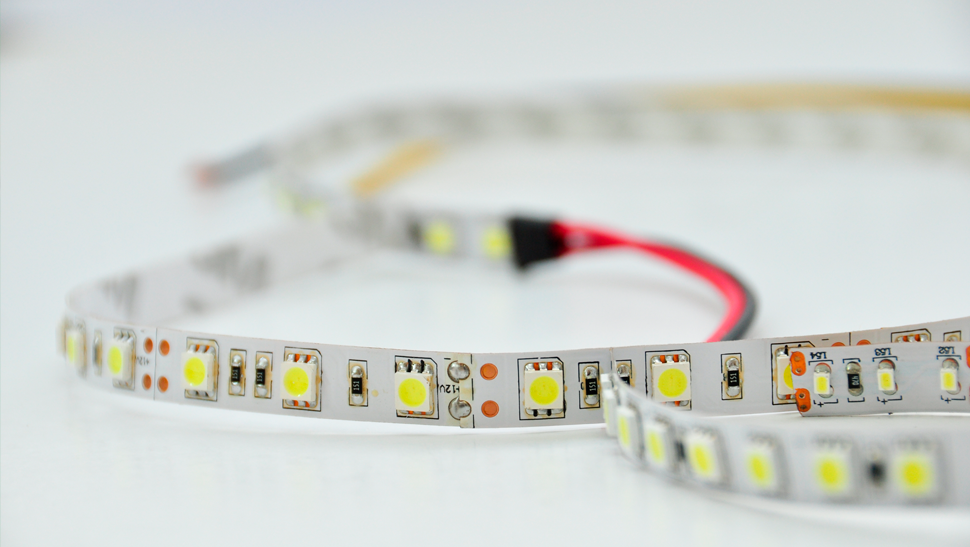

The MY700JX is without question the most flexible way to produce complex boards at speeds of more than one million dots per hour. It handles flexible substrates, LED boards, cavities and package-on-package applications with ease. And a non-contact nozzle precisely jets solder paste deposits with complete volume control, ensuring repeatable quality and higher throughput with less re-work.

With the same machine you can dispense glue or other assembly fluids for encapsulation, selective coating, dots and lines at the industry’s absolute highest speeds.

More capabilities. Less equipment.

Extremely versatile and compact, the MY700JX is an ideal fit almost anywhere on your factory floor. From perfect fine-pitch solder deposits to long connectors and flux dots, you can achieve higher precision than with stepped stencils and higher speeds than with general dispensers.

Smart board handling

Adjustable conveyor rails make it easy to switch between single- or dual-lane setups, while two internal buffering options provide optimized work

area and loading times. The dual-lane configuration virtually eliminates board loading time by ensuring that while one board is printing, the other is already being loaded and in jetting position in the second lane. Whatever applications your operations might demand, the MY700’s best-in-class machine depth guarantees a large work area with generous top and bottom side clearance.

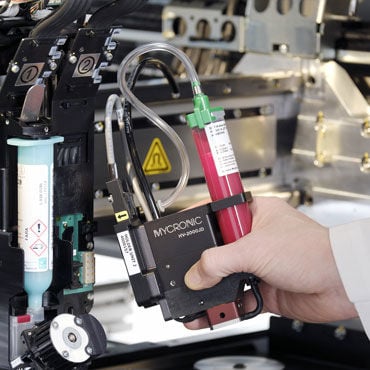

Unique dual-head ejectors

The ultimate in space productivity

Contact