Stretching the limits of wearable electronics

Deep in the snow-capped mountains of Sweden, the national cross-country ski team will soon not only be pushing their limits in the tracks, but testing stretchable electronic sensors to monitor heart rate, stress, glucose levels and more.

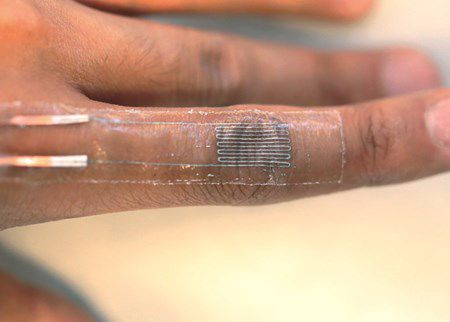

Unlike standard wearable devices that tend to be bulkier, stiffer and create friction, the new multi-sensors stick like hair-thin tape (100 microns) to the skin, are ultra-light and stretch to fit the contours of a finger, arm or leg.

“IF ALL GOES WELL, this next generation of wearable electronics can be used not only for sports but healthcare and other applications,” says Gustaf Mårtensson, an expert in complex fluids at Mycronic, one of eight companies in the EU-financed SINTEC project.

“For me personally it feels like a gift not only to be enabling the future of electronics but improving the health prospects for millions of Europeans – and even creating jobs for a whole new industry. All of us on the SINTEC team are really fired up about making it happen.”

Next-generation wearables

According to Mårtensson, the growing interest in advanced physiological monitoring is being driven by a global trend towards wireless-enabled wearable devices. “Most people know how a smartwatch, for example, allows you to measure steps walked, heart rate, quality of sleep and other metrics. Now we are taking this to a whole new level in terms of lightness, accuracy, comfort and the possibility to capture hidden data by being in direct contact with the body.”

Robust, stretchable and sustainable

“Imagine applying a tape-thin sensor to an elderly patient that hugs their body and moves with them, monitoring their heart and other functions,” Mårtensson says. “The big challenge is making it robust enough to stretch and twist, while containing ultra-thin, interconnecting circuitry on multiple levels. Another challenge is utilizing sustainable, non-toxic materials, such as Galinstan, a metal alloy for liquid circuitry, that stays liquid down to –19°C (–2°F).”

Goal: develop a working production line

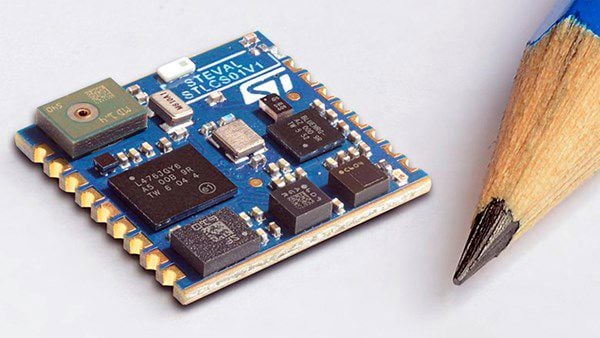

As a high-tech company with fully integrated PCB manufacturing technology, Mycronic was asked to help develop this hybrid stretch PCB technology. The goal of the four-year project, which ends in 2023, is to find a commercial solution for the actual production of stretchable electronics, including achieving a higher degree of maturity in several technical challenges.

For Mycronic, this means implementing a working production line using the products and technologies in its product portfolio, including conformal coating, dispensing, pick-and-place, and inspection. “Now, it’s full speed ahead!” says Mårtensson.

Eight partners in the SINTEC project

The European Horizon 2020 research project SINTEC (Soft Epidermal Communication Platform) includes the following partners:

Academic Partners

- Engineering Sciences at Uppsala University (Sweden)

- Swedish National Winter Sports Center at Mid Sweden University (Sweden)

- LINKS at Polytechnic of Turin (Italy)

Company Partners

- Mycronic AB (Sweden)

- ST Microelectronics (French-Italian)

- Warrant Hub (Italy)

- Evalan (The Netherlands)

- MySphera (Spain)

This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement no. 824984. www.sintec-project.eu.