Agilis Smart Bin

Paperless productivity – changeover guidance with Agilis Smart Bin.

MISSING COMPONENTS. Sticky notes falling off. Hunting for information. The list of reasons for unplanned downtime could go on. But in most cases, line utilization is heavily dependent on efficient material and information handling.

Lower changeover cost with Agilis Smart Bin system

The most common reason for unplanned downtime in high-mix electronics manufacturing is missing material. The Agilis Smart Bin system will help machine operators minimize downtime by ensuring that all needed material is collected and prepared just-in-time for production.

Building on our already powerful material handling solutions, including the MYTower automated storage, the Agilis Smart Bin system brings unparalleled ease-of-use to the kitting and changeover process. The end result is faster changeovers and higher utilization – improving your bottom line.

Key benefits

- Paperless kitting guidance and changeover instructions – right in front of you

- Preload in Agilis Bins for upcoming jobs – without losing track of material location

- Easily locate missing components wherever they are

- Faster changeovers and higher utilization

|

|

|

|

|

|

Empty bin. |

Pre-loading bin. F-375 according to MYCenter guidance. |

Kitting complete. Insert magazine in machine MY100B, slot 7. |

Machine running. Keep magazine in machine MY100B, slot 7. |

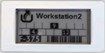

Changeover. Bring reels in positions 4, 9 and 12 to Workstation 2. |

Complete kitting and changeover guidance

The intuitive instructions are presented where the actual work takes place, directly on the material container, minimizing unnecessary movements across the factory floor in search for information.

The upper-left side of the e-label shows an icon for easy indication of the bin’s material status: kitting ongoing, ready to bring to machine, ready for changeover, etc. To the right of the icon, the operator can view primary instructions such as machine name, feeder slot, the material destination during changeover, and more.

How it works

The Agilis Smart Bin system provides intuitive paperless kitting guidance, based on wireless, electronic labels (e-labels) that communicate with the central data server via a radio base station. Each Agilis Smart Bin is equipped with an e-label that is mechanically attached to the front of the bin.

The MYCenter Material Handling software guides the operator through the entire kitting and changeover process, by presenting instructions on the PC monitor, but also on the e-labels. All actions are confirmed using the hand-held barcode scanner.